Environmental Engineering Reference

In-Depth Information

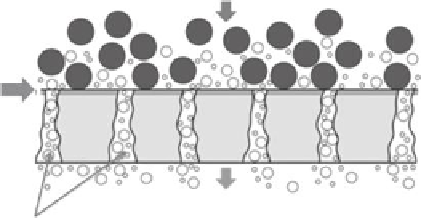

Raw water (feed)

Membrane surface

Purified water (permeate)

Membrane pores

FIGURE 20.4

Basic structure of a membrane. (From http://www.hydrogroup.biz/areas-of-use/water-treatment/membrane

-iltration.html, accessed November 22, 2012.)

Ultrafiltration

Reverse osmosis

Microfiltration

Nanofiltration

0.2 µm

0.1 µm

0.01 µm

0.001 µm

Raw water

e following

substances can

be held back:

Plankton

Algae

Turbidity

Bacteria

Suspended

substances/

solids

Macro-

molecules

Viruses

Colloids

DOC

Large

ions

Ions

Required trans-

membrane pressures:

0.2-5 bar

1-10 bar

5-10 bar

10-150 bar

FIGURE 20.5

Classiication of membranes and types of substances that can be separated by each one of them. Included are

the pressures required to drive water across each membrane type. (From http://www.hydrogroup.biz/areas-of

-use/water-treatment/membrane-iltration.html, accessed November 22, 2012.)

In most cases, it is the structure of the membrane that dictates its application. Thus, the

membranes can be classiied into membrane bioreactors, low-pressure membranes, and

high-pressure membranes:

1. Membrane bioreactors: These include MF or UF membranes immersed in aeration

tanks (vacuum system), or implemented in external pressure-driven membrane

units, as a replacement for secondary clariiers and tertiary polishing ilters.

2. Low-pressure membranes: These include MF or UF membranes, either as a pres-

sure system or an immersed system, providing a higher degree of suspended sol-

ids removal after secondary clariication.

3. High-pressure membranes: These include NF or RO pressure systems for treat-

ment and production of high-quality product water suitable for indirect potable

reuse and high-purity industrial process water.