Environmental Engineering Reference

In-Depth Information

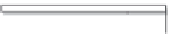

Water out

(a)

Hollow glass tubes

Reflector

Steel casing

Converging lens

TiO

2

and SiO

2

coating

Light source

Water in

TiO

2

and SiO

2

coating

(b)

Light in

Reflector

FIGURE 1.2

(a) Schematic diagram of photocatalytic reactor. (b) Schematics of one hollow tube.

1.5 Conclusion

The work conducted has shown that crumb rubber is an effective iltration medium because of

its favorable porosity gradient. The bottom layer comprising coarse rubber particles does not

promote clogging of the iltration column. The iltered water showed a small head loss (7 cm) at

high iltration rates such as 20 m/s. The turbidity was reduced to low levels (3.0 NTU), suspended

solids were not observed, and the TDS showed lower levels. Exposure of water obtained from

the iltration column showed no evidence of the presence of

E. coli

,

Shigella

spp., and

V. c h o l e r a e

.

The application of the bimodal technique of crumb rubber iltration and UV-supported

n

-TiO

2

catalysts showed a signiicant improvement in water quality. The physiochemical characteris-

tics of water matched the standards invoked by WHO. The current work on the scaling up of a

photocatalytic reactor is based on using hollow nanostructured tubes coated with mesoporous

TiO

2

and

n

-SiO

2

for uniform relection of light. It is expected that this work shall enable the

scaling up of the photocatalytic reactors and allow a new generation to treat the wastewater

from the textile, agricultural, and chemical industries, which is highly challenging.

Acknowledgments

The authors thank Faheemuddin Patel of KFUPM, Dhahran, Kingdom of Saudi Arabia, for

his help in the work done on crumb rubber iltration, and Rizwan Ahmad of COMSATS for

his contribution in designing the photocatalytic reactor. The help provided by Zahra Khan

and Tayyaba Abid is appreciated.