Environmental Engineering Reference

In-Depth Information

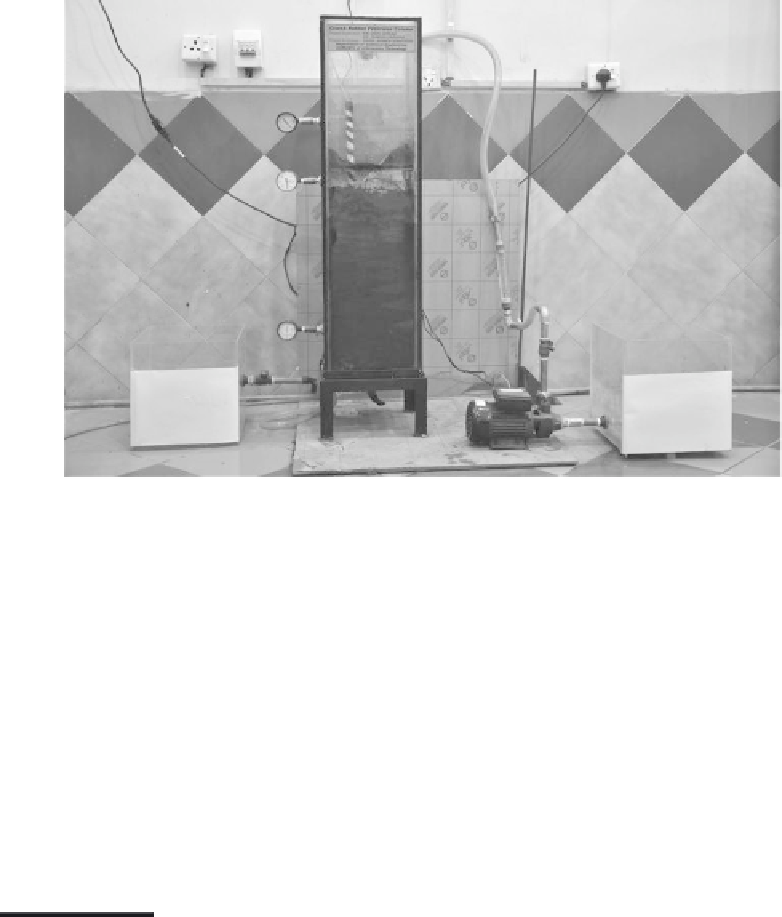

FIGURE 1.1

(See color insert.)

Crumb rubber reactor.

placed on top of the iltration unit after turning on the vacuum pump. The membrane ilter

was removed and placed on a Petri dish, and was sealed with tape. Incubation was done at

35°C for 30 h. Dark-colored (pink) areas representing the colonies were used for counting

under a dissecting microscope. The density was counted as

Coliform/100 ml = (No. of colonies counted) × 100/sample size (ml)

A geometric mean was taken while calculating the average coliform density. A dehydrated

commercial media was used.

1.4 Results and Discussion

1.4.1 Suspended Solid Concentration

After a run of 12 h at 4 gpm/ft

2

(gpm = gallons per minute), the suspended solid concen-

tration was reduced from 10.5 to 7 mg/l, which was a signiicant reduction. After a sum

of 16 h, the reduction was only 8.5 mg/l. In the values reported in the literature, the sus-

pended solid content decreased to 5 mg/l from the initial concentration of 8.4 mg/l.

The turbidity values showed a decrease of 2-3 NTU, which indicates a good turbidity

removal. The head loss observed was only 4.0 in, which was much lower than in conven-

tional iltration media such as sand/anthracite and gravel. The small head loss observed

with crumb rubber is a major advantage of crumb rubber iltration. The advantage of

using crumb rubber is a favorable porosity gradient, i.e., inest at the top and coarse at