Environmental Engineering Reference

In-Depth Information

1,000,000

900,000

800,000

700,000

600,000

500,000

400,000

300,000

200,000

100,000

0

0

Untreated

Osorb treated

5

10

15

20

25

30

35

Time (min)

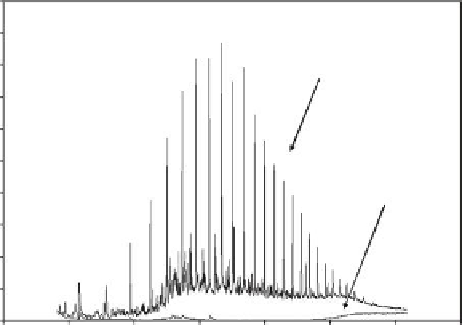

FIGURE 8.12

Gas chromatograms of Clinton formation produced water before and after treatment with PWUnit#1.

internal low pressure point when the rate of incoming water is above a certain threshold.

This low pressure point then creates suction through four small openings in the back of

the nozzle, allowing the nozzle to draw in the water/Osorb mixture that is present in the

tank. The nozzles were able to draw in 3 gal of slurry for every 1 gal of water that is deliv-

ered from the produced water stream. The sorbent was separated from the water using a

screen and sent for regeneration, which can be accomplished on site.

The 60 gpm treatment system was tested on produced water from the Clinton formation

in central Ohio. The test water contained a mix of both heavy and light hydrocarbon ana-

logs of a mixture of both type A and B produced water. A treatment of >99% was obtained

in the luidized bed design using 1% w/v Osorb addition (Figure 8.12). Regeneration was

performed as part of this pilot project. These tests indicate that regeneration is the rate-

limiting step in Osorb treatment, in part due to the manual labor involved in the initial

design. A signiicant amount of investigation is being conducted to engineer an automated

regeneration system.

8.4 Economics of Produced Water Treatment

The largest cost of operating an oil and gas well is the cost of managing the water. For

every 1 bbl (= 42 gallons) of valuable hydrocarbons produced from a well, 2-20 bbl of

produced water must be managed. Oil producers understandably view produced water

from oil ield operations as any other cost center. Produced water is managed in whatever

manner most inexpensively removes the cost from the project. For onshore production in

North America, nearly all produced water is trucked, or taken by pipeline to a disposal

well. Disposal wells are primarily drilled into highly permeable deep Earth formations.

In many cases, produced water is injected within the same layer producing the hydro-

carbons. This process serves both the needs for disposal and the need to keep a forma-

tion stable and pressurized. The cost of disposing of water at a disposal well ranges from