Environmental Engineering Reference

In-Depth Information

Hydrophobic

barrier

(a)

(b)

Matrix tension

Void volume

New surface area

Dissolved hydrocarbons

(c)

(d)

Continued matrix expansion

FIGURE 8.5

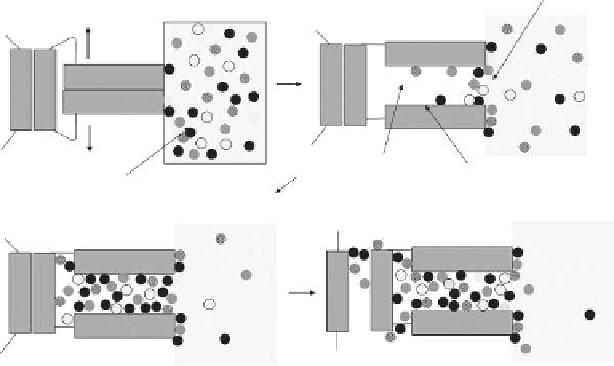

Proposed model for absorption of dissolved organics by swellable glass media. (a) Initial adsorption to the

surface of the material. (b) Suficient adsorption occurs to trigger matrix expansion leading to absorption

across the sorbent-water boundary. (c) Pore illing leading to further percolation into the nanoporous matrix.

(d) Continued matrix expansion increases available void volume.

matrix, leading to nonselective capture of organics beyond what could only be attributed

to physisorption. It was observed in previous work that the force produced during swell-

ing was not continuous with respect to swollen volume but exhibited a stepwise behavior.

16

Thus, it appears that once a particular amount of contaminant is

ad

sorbed it “unlatches”

the matrix to yield void volume for subsequent

ab

sorption events (Figure 8.5). In all cases,

log

k

> log

K

ow

; in other words, the partitioning into Osorb is greater than what would be

predicted on the basis of standard liquid-liquid extraction, suggesting that there is an addi-

tional thermodynamic driving force for absorption. A likely explanation for the enhanced

partition coeficients is that an increased Osorb entropy upon swelling can compensate for

entropic and enthalpic barriers to absorption. What is quite unique about Osorb is that sol-

utes condense as liquids (or solids depending on identity) in the Osorb matrix. Absorption

by Osorb is fundamentally condensation in the pore structure, not adsorption through

intermolecular forces of attraction between organic and the Osorb surface, although initial

absorption events serve to unlock the matrix. Evidence for condensation of absorbates has

been obtained using infrared spectroscopy to probe the physical state of captured solutes

within the matrix.

8.2.3 Effect of Process Conditions

Variations in salt concentration, temperature, and pH are typically encountered when

treating produced water streams. For instance, the total dissolved solids (TDS) in pro-

duced water can generally range from 5000 to 100,000 ppm, and in some cases can be

much higher. Sodium chloride is the most abundant dissolved solid, although group I and

group II metal sulfates are also relatively common. Treatment technologies need to be able

to handle high variability in the amount and types of dissolved solids. Temperature of