Environmental Engineering Reference

In-Depth Information

Hydrolysis

Si

OR

+

HOH

Si

OH

+

ROH

Water

condensation

Si

OH

+

Si

OH

Si

O

Si

+

HOH

Alcohol

condensatio

n

Si

OH

+

Si

OR

Si

O

Si

+

ROH

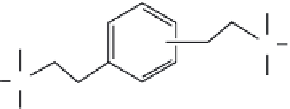

FIGURE 8.1

Sol-gel process begins with hydrolysis of alkoxysilane. Silanol can condense with another silanol or an alkoxy

group to form a Si-O-Si linkage.

condensation, resulting in the three-dimensional, porous siloxane network that constitutes

the gel. The solvent in the interstitial space is then removed by evaporation to create solids

that have various nanoscale to microscale morphologies, possessing chemical functional

groups based on the choice of precursor. A wide range of materials can be produced; from

dense glasses, to highly ordered porous materials, to ultralow density aerogels.

8

The sol-

gel process is a convenient method to prepare hybrid inorganic-organic materials with

unique properties both in terms of chemical composition and physical microstructure.

There is a substantial variety of organically modiied alkoxysilanes possessing different

types of chemical groups, which facilitates a wide diversity of materials to be prepared

using a common synthetic scheme. Bridged precursors are a subset of organically modi-

ied silanes where two silicon centers are tethered by an organic group (RO)

3

-Si-Y-Si(OR)

3

,

where Y is the bridging group and -OR is the polymerizable alkoxide group. The advantage

to such a structure is that polymerization can radiate from two directions and the bridge

group can act as a structure directing unit.

9,10

Polycondensation of bridged precursors have

been reported and subsequently used to create nanostructured materials.

11,12

Control of

the sol-gel processing conditions (e.g., solvent, catalyst, aging temperature) can be used

to tailor the texture of the resulting sol-gel-derived solids, which is advantageous when

designing new materials.

13

Highly animated materials have been created by using molecu-

lar self-assembly as a structure-directing process to control the nanomechanical properties

of polymeric organosilicate.

14

The resulting material is commercially available as Osorb.

Osorb is a nanoengineered sol-gel-derived material that rapidly swells about four to ive

times its dried volume and swells up to eight times its dry mass in nonpolar solvents, but not

water. Before the discovery of Osorb, sol-gel-derived solids were characterized as inelastic

and not able to swell after preparation. The highly animated nature of Osorb is derived

from the polymerization of a bridged organosilane precursor bis(trimethoxysilyethyl)

benzene (Figure 8.2) under carefully controlled conditions, including the use of THF as a

OCH

3

OCH

3

Si

OCH

3

H

3

CO Si

OCH

3

OCH

3

FIGURE 8.2

BTEB structure.