Environmental Engineering Reference

In-Depth Information

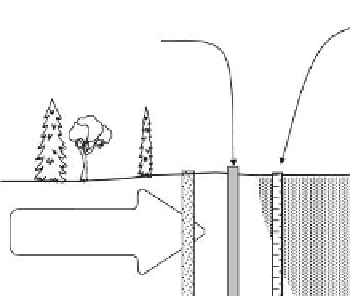

Nest of

monitoring

wells

Nest of treatment

wells

Surrounding sheet-pile

wall

Direction of

groundwater flow

Optional treatment

zone with

enhanced NA

capabilities

Contaminated

region

Impervious clay layer

FIGURE 10.19

Containment of contaminants in a contaminated site using a conining sheet-pile wall that surrounds the

contaminated region. The sheet-pile wall is sunk into the impervious clay layer to prevent bottom escape of

contaminants. Treatment wells are sunk into the contaminated regions, and monitoring wells are placed down-

stream with some upstream also. Optional treatment zones using enhanced NA capabilities can be used, if

needed.

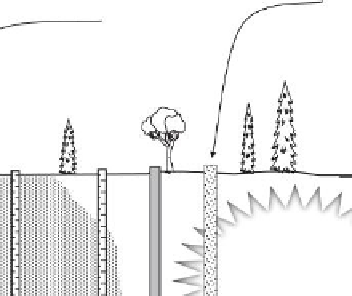

and if site hydrogeology is well understood, the solution shown in Figure 10.20 is one that

utilizes the capabilities of enhanced NA in combination of the permeable reactive barrier

(PRB) previously described. This procedure is both a mitigation and management tactic for

management of contaminant impact. Note again that the monitoring and treatment wells

are somewhat simplistic in illustrative portrayal.

The engineered barrier systems for a municipal and a hazardous waste landill shown

in Figure 1.11 are good demonstrations of the extent to which composite barrier systems

can be designed and engineered to meet the requirements for management and control of

contaminants. The details of the ilter, membrane, and leachate collection system are speci-

ied by regulatory

command and control

requirements or by performance requirements. In

the case of the MSW landill liner system shown in the bottom right-hand corner of Figure

1.11, the soil material comprising the engineered clay barrier underlying the synthetic

membrane must possess hydraulic conductivity values that are below the maximum per-

missible values. The basic idea in the design details of the engineered barrier for the MSW

landill is that if leachates inadvertently leak through the high density polyethylene mem-

brane (HDPE) and are not captured by the leachate collection system, the contaminants in

the leachate plumes will be attenuated by the engineered clay barrier. The engineered clay

barrier serves as the second line of defense or containment.

For the hazardous waste (HW) bottom liner system shown in the bottom left-hand cor-

ner of Figure 1.11, there are two lines of defense before the soil sub-base. The high-density

polyethylene (HDPE) acts as the irst barrier. Before this, the leachate collection system is

Search WWH ::

Custom Search