Environmental Engineering Reference

In-Depth Information

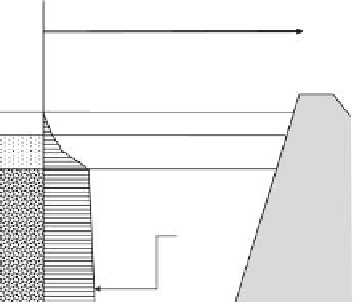

Increasing solids concentration

Supernatant

Transition zone

Stagnant zone

containing

recalcitrant

suspended solids

Solids

concentration

profile

Sediment

FIGURE 5.10

Illustration showing solids concentration proile for the recalcitrant suspended solids behavior pattern - typical

of such sludges and slimes as red muds, tar sands sludges, phosphatic, and other clay slimes.

Phosphate slime

sc ≈ 13 to 20%

Phosphate rock digestion, acidulation,

and wet process phosphoric acid

production, concentration, clarification

and superphosphate production.

Soil-organic slime

sc ≈ 2 to 20%

Wet milling of humate-cemented

sand grains for extraction of heavy

minerals.

Oil sands sludge

sc ≈ 40 to 44%

Sludge from hot water

extraction process for

bitumen from oil sands.

Bauxite red mud

sc ≈ 20 to 40%

Bayer processing of bauxite

for extraction of aluminium.

Beneficiation slurry

sc ≈ 8 to 10%

Discharge wash from extraction of

clay coated coal ore.

Aggregate slime

sc ≈ 12 to 18%

Wash-extraction of coarse

aggregates from weathered granite.

Tin mining slime

sc ≈ 48 to 54%

Gravel-pump mining discharge from

hydraulic mining of placer deposits.

Clay coating slurry

sc ≈ 50 to 54%

Clay coating slurries in kaolin mineral

processing for paper coating.

[

sc = solids concentration

]

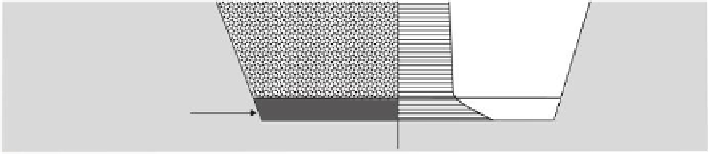

FIGURE 5.11

Some examples of slurries, slimes, and sludge found in holding ponds. The solids concentrations (sc) are

obtained from results reported by Yong and his colleagues (see, for example, Yong, 1984). Details of the compo-

sitional features of the slurries, slimes, and sludge are given in Table 5.3.

Search WWH ::

Custom Search