Environmental Engineering Reference

In-Depth Information

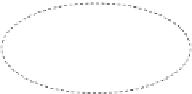

(a)

Recovery well

(b)

Fracture fluid delivered

under high pressure

Fracture fluid delivered

under high pressure

Steam injection

Surface

Steam-affected zone

Fracture zone

acture zone

FIGURE 5.4

Elements of steam-assisted gravity drainage (SAGD) process for recovery of heavy bitumen (a) and hydrau-

lic fracturing of shale or other hydrocarbon-containing geologic feature (b). Note that capture of the released

hydrocarbons in fracking process is affected by other capture wells.

generation is brought about using high-pressure fracking luids. The types of fracture-

luid commonly used consist of water and sand or other products capable of producing

physical actions necessary to keep the produced fractures open to allow for recovery of

the hydrocarbons of interest (natural gas or

tight oil

). This sand-water mix will generally

contain various types of chemicals, such as (a) water-soluble gels, (b) chemical additives

that have the capability of maintaining fractured openings open, (c) additives needed to

inhibit bacterial growth, and (d) chemicals required to maintain eficiency of delivery of

the fracturing luid such as surfactants, corrosion inhibitors and friction reducers.

5.2.4 Sulfide Minerals and Acidic Leachates

We consider the case of production of acidic leachates from mining and extraction of sul-

ide minerals as a separate issue from the detailed discussions that begin in Section 5.5.2.

This is because of the signiicant problems and stressors generated by sulidic metallifer-

ous rocks, and by their impacts on the geoenvironment—the most common or prominent

issue being the generation of acid mine drainage (AMD) and the release of arsenic from

their host rock ores.

5.2.4.1 Acid Mine Drainage

The sulide minerals in the host rock in the mines and in the ores such as iron sulides,

pyrites, arsenopyrites, chalcopyrites, pyrrhotites, sphalerite, and maracasites present severe

Search WWH ::

Custom Search