Environmental Engineering Reference

In-Depth Information

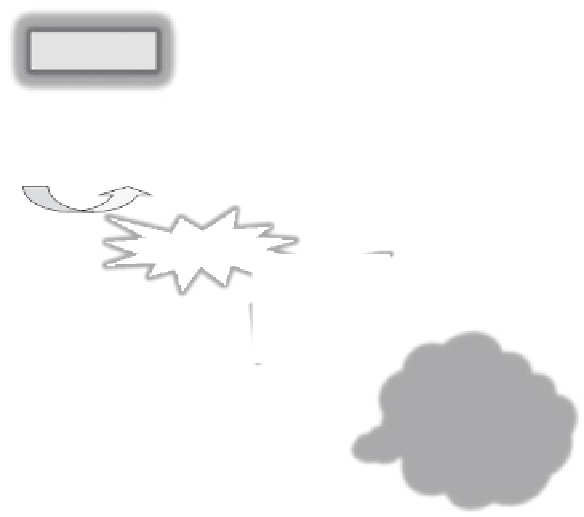

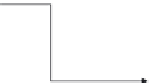

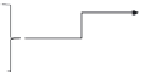

electrical resistance, hardness, chemical resistance, and tarnish resistance metals. Figure

4.3 gives an example of the processes associated with metal fabrication. The sources of

solid and liquid waste discharges are seen in the diagram. Most of the chemicals used in

the metals inishing business end up as wastes. Considering that the various inputs to the

processes include acids, solvents, alkalis, cyanide, loose metals, and complexing and emul-

sifying agents, it will not come as a surprise to note that the waste discharge and waste-

waters can contain these chemicals and various other residues, especially since many of

the processes include rinsing and bathing operations. These wastes predominately result

from the use of (a) organic halogenated solvents, ketones, aromatic hydrocarbons, and

acids during the surface preparation stage of the overall inishing process and (b) cyanide

and metals in the form of dissolved salts in the plating baths during the surface treatment

stage. These will all be found in the discharge streams shown in the bottom right of the

diagram in Figure 4.3, as sludge, solid waste, and wastewater.

In the pig iron production process, the lue dust generated is captured by wet dust clean-

ers. In common with most of the typical metal inishing processes shown in Figure 4.3,

steel inishing involves a number of necessary processes in the production of the desired

surface and mechanical characteristics for the steel. The sulfuric acid used in most pick-

ling processes creates hazardous by-products. Pickling solutions contain free acids, fer-

rous sulfate, undissolved scale and dust, and the various inhibitors and wetting agents as

well as dissolved trace elements. The concentration of acids and their types largely depend

on the type of iron being produced. Finishing operations generate efluents containing

rolling oils, lubricants, and hydraulic oils that are in free and emulsiied states. Other oils

Alkalis, acids, solvents,

emulsifying agents

Solid waste

Metal fabrication

cutting and forming

Rinsing and

bathing

Metal preparation

cleaning

Rinsing and

bathing

Acids

Wastewater

Cyanide,

Acids,

Alkalis,

Metals

Anodizing

Electroplating

Chemical conversion

Plating

Painting

Other

Sludge

solid waste

wastewater

Metals, acids

Complexing

agents,

metals, acids

Paints, solvents

FIGURE 4.3

Processes and waste products generated in metal fabrication and preparation. (Adapted from EPA,

Proile of

Metal Products Industry

, Washington, DC, Ofice of Enforcement and Compliance Assurance, 1995.)

Search WWH ::

Custom Search