Environmental Engineering Reference

In-Depth Information

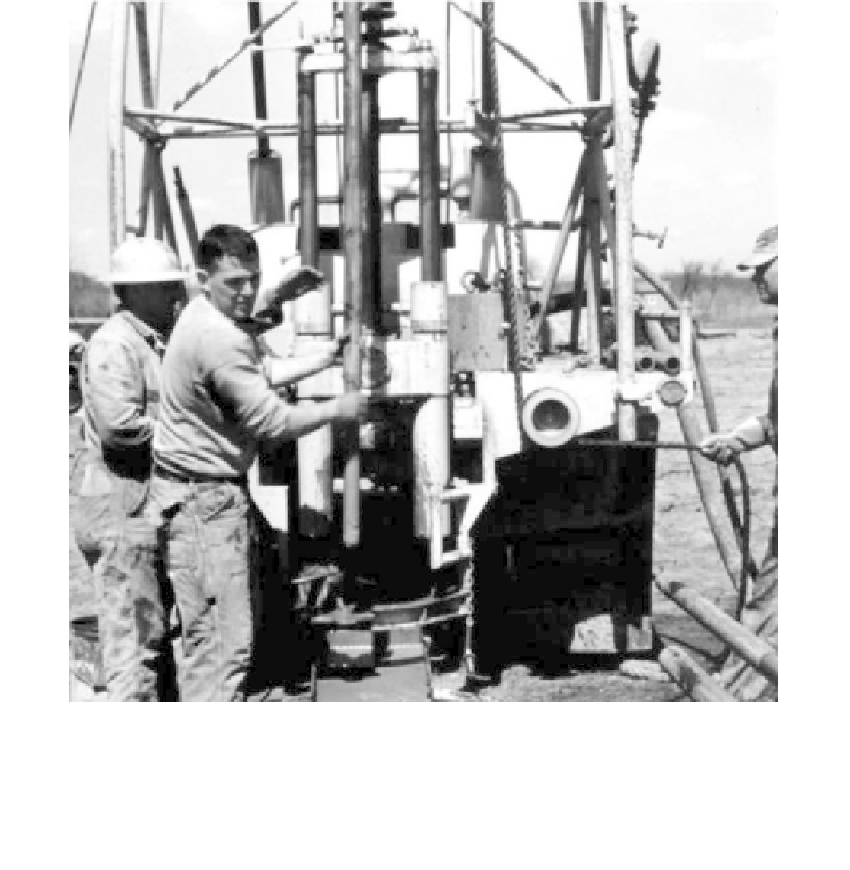

FIGURE 2.50

Rotary drilling with a truck-mounted Damco drill rig using mud slurry to prevent hole collapse. Rope on the

cathead is used to lift rods to drive the SPT sampler, which in the photo is being removed from the hole. A

hydraulic piston applies pressure to rods during rock coring, or during pressing of undisturbed samples. The

table supporting the hydraulic works is retractable to allow driving of SPT samples or casing.

Drilling bits

are used to cut soil or rock; some common types are shown in

Figure 2.53.

Chopping bits (others such as fishtail or offset are not shown) are used for wash borings.

Drag bits (fishtail or bladed bits) are used for rotary soil boring. They are provided with

passages or jets through which is pumped the drilling fluid that serves to clean the cut-

ting blades. The jets must be designed to prevent the fluid stream from directly imping-

ing on the hole walls and creating cavities, or from directing the stream straight

downward and disturbing the soil at sampling depth. Low pump pressure is always

required at sampling depth to avoid cavities and soil disturbance. Rock bits (tricone,

roller bit, or “Hughes” bit) are used for rock drilling. Core bits (tungsten carbide teeth

or diamonds) are used for rock coring while advancing the hole. Sizes are given in

Sampling tools are described in

Section 2.4.

Standard Boring Procedures

1.

Take surface sample. (In some cases, samples are taken continuously from the

surface to some depth. Sampling procedures are described in

Section 2.4.2.)