Environmental Engineering Reference

In-Depth Information

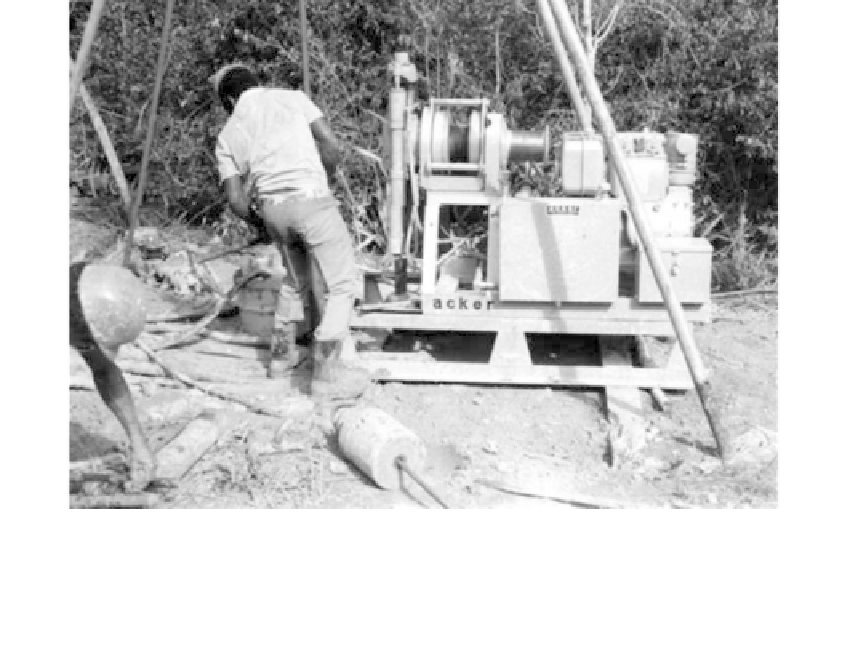

FIGURE 2.49

A skid-mounted rotary drilling machine which advances the hole in soil or rock with a cutting bit on the end

of a power-driven rotating drill rod to which pressure is applied by a hydraulic ram. In the photo, the drill

rods are being lowered into the hole before the hole is advanced.

dimensions are given in

Table 2.14;

casing is designed for telescoping. There are several

types of casing as follows:

Standard drive pipe

has couplings larger than the outside pipe diameter and is

used for heavy-duty driving.

●

Flush-coupled casing

has couplings with the same diameter as the outside pipe

diameter. For a given diameter, it is lighter and easier to drive because of its

smooth outside surface than a standard pipe, although more costly to purchase.

●

Flush-jointed casing

has no couplings and is even lighter in weight than flush-cou-

pled casing, but it is not as rugged as the other types and should not be driven.

●

Drill rods

connect the drilling machine to the drill bits or sampler during the normal test

or core boring operation with rotary machines (or tripods for soil borings). Standard sizes

are given in Table 2.14. Selection is a function of anticipated boring depth, sampler types,

and rock-core diameter, and must be related to machine capacity. The more common

diameters are as follows:

“A” rod is normally used in wash boring or shallow-depth rotary drilling to take

SPT samples. In developing countries, a standard 1 in. pipe is often substituted

for wash borings because of its low weight and ready availability.

●

“B” rod is often used for shallow rotary core drilling, especially with light drilling

machines.

●

“N” rod is the normal rod size for use with large machines for all sampling and cor-

ing operations; it is especially necessary for deep core drilling (above 60 ft or 20 m).

●

“H” rod is used in deep core borings in fractured rock since it is heavier and

stiffer than “N” rod and will permit better core recoveries.

●