Environmental Engineering Reference

In-Depth Information

components required for test or core borings include a drilling machine, casing, drill rods,

drilling bits, and sampling tools.

Drilling machines

consist of a power source, a mast for lifting apparatus, and a pump for

circulating water or mud (or a compressor for air drilling) to lower, rotate, and raise the

drilling tools to advance the hole and obtain samples. Test borings for obtaining represen-

tative or undisturbed samples under all conditions are normally made by rotary drills, and

under certain conditions, with the tripod, block, and tackle. Some of the more common

machines are illustrated in Figures 2.48 through

2.51

.

Exploratory holes in which only disturbed samples are obtained are made with contin-

uous-flight augers, large-diameter augers in clays or by percussion or hammer drilling in

all types of materials. Large-diameter augers (

Figure 2.52)

can provide holes of diameters

adequately large to permit visual examination of the borehole sides for detailed logging,

if the inspector is provided with protection against caving. Pneumatic percussion and

impact drills advance holes rapidly in rock, without core recovery.

Casing

is used to retain the hole in the normal test boring operation, with tripods or

rotary machines, at the beginning of the hole and for the cases described under Hole

Stabilization. Boring cost is related directly to casing and hole size. Standard sizes and

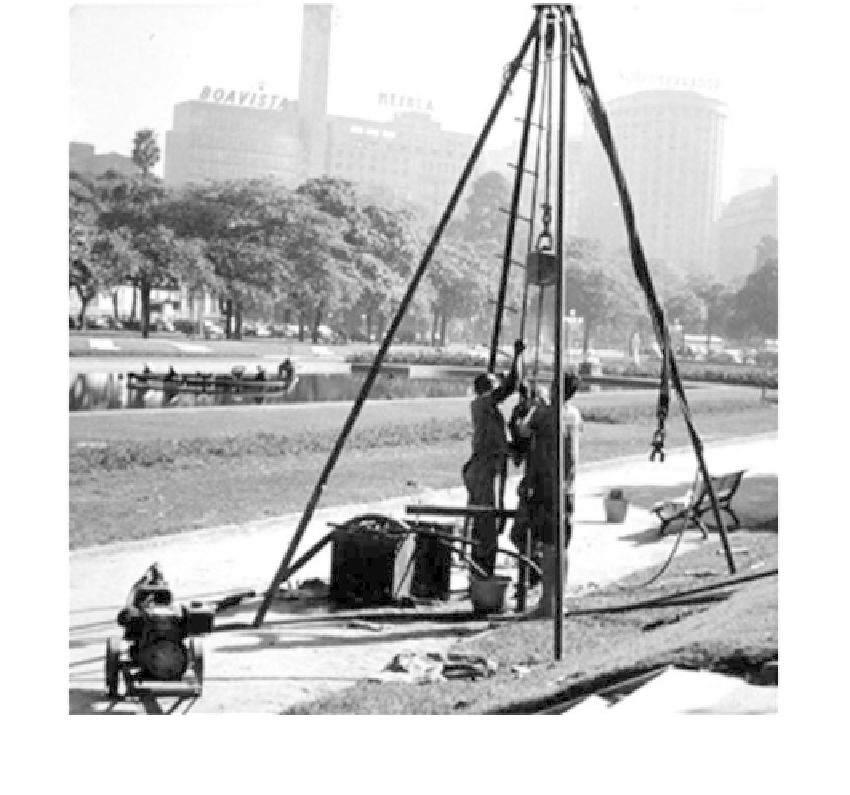

FIGURE 2.48

The wash boring method. The hole is advanced by hand by twisting a bladed bit into the soil as water under

pressure removes cuttings from the hole. In the photo, a 140 lb hammer is being positioned before driving an

SPT sample.