Environmental Engineering Reference

In-Depth Information

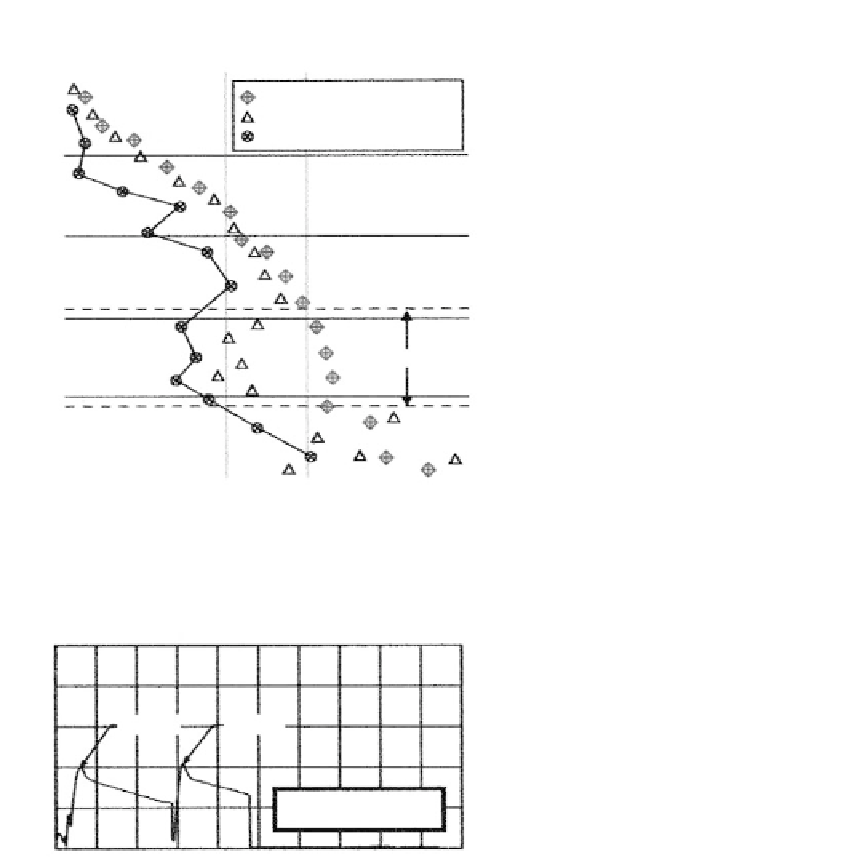

Undrained shear strength (ksf)

0

1.0

2.0

3.0

4.0

0

Remote vane data

3.0-in. pushed data

2.25-in. driven data

100

200

300

Gassy

400

500

Deepwater site

Time (sec.)

0

200

400

600

800

1000

2.5

2.0

S

u

=1.00

S

u

=1.04

1.5

1.0

FIGURE 2.47

Remote vane results compared with lab test

results from push samples. (Courtesy of

Fugro.)

Blade : Small

Depth: 33.0 & 35.0 (ft)

0.5

0

Boring Inclination

Vertical borings

are normal in soil formations and most rock conditions during

investigation.

●

Angle borings

are often drilled in rock masses to explore for joints, faults, or solu-

tion cavities, or for the installation of anchors in soil or rock.

●

Horizontal borings

are drilled to explore for tunnels or the installation of rock bolts,

instrumentation, or horizontal drains. Maintaining a straight horizontal boring is

extremely difficult. At the start of the boring, gravity tends to pull the drill bit

downward; then as penetration increases, gravity acts on the heavy drill string and

the bit may tend to drift upward. Rock quality variations will also cause inclination

changes. New technology employs directional drilling (Civil Engineering, 1998).

●

Standard Drilling Machines and Tools

There are a large number of hole-making methods and drilling machines. A summary is

given in

Table 2.13

in terms of application, method, advantages, and limitations. The basic