Environmental Engineering Reference

In-Depth Information

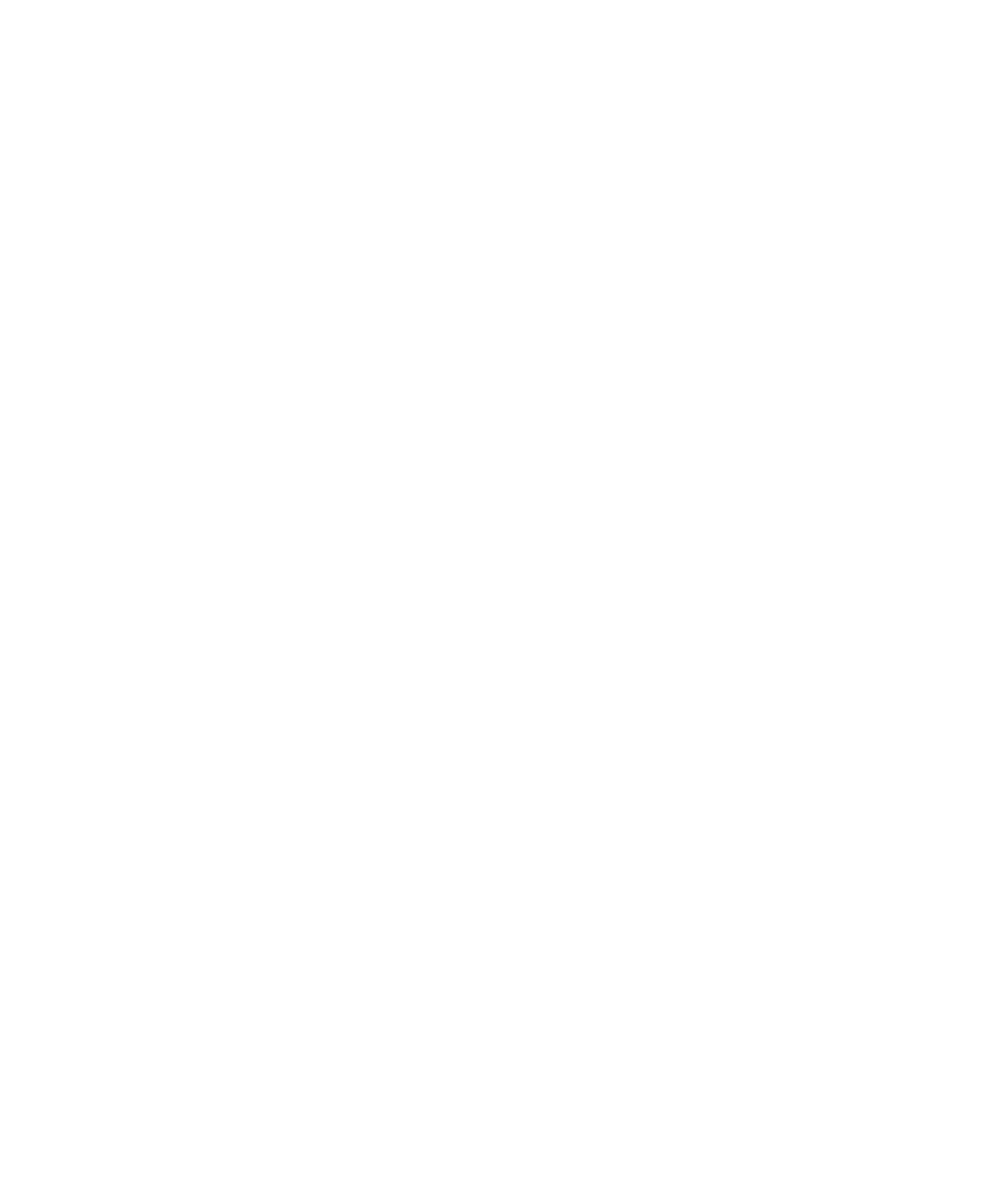

Spacing of wellpoints (ft)

Poles

Ground water

lowering

(ft)

1

1

1

60

50

Gravel

O

1

2

Very fine

gravel

O

40

2

5

10

Gravel

2

2

3

4

5

30

25

1

3

Coarse

sand

O

20

3

4

15

2

10

4

5

3

4

5

15

Very fine

gravel

1

9

8

7

6

5

5

6

Medium

sand

O

10

7

8

10

9

15

4

10

Coarse

sand

15

3

Fine

sand

15

2

Medium

sand

Fine

sand

O

1

FIGURE 8.43

Wellpoint spacing for stratified sands and gravels. (From Mansur, C.I. and Kaufman, R.I.,

Foundation

Engineering,

G.A. Leonards, 1962 and Griffin Wellpoint Corp.)

wellpoints. There must be a sufficient depth of pervious materials below the level to which

the water table is to be lowered to permit adequate submergence of the well screen and

pump. Deep wells are particularly effective in highly stratified formations containing free-

draining gravels. They are used also to dewater tunnels and to stabilize deep-seated slide

masses, but they are costly and continuous pumping is required to maintain stability.

Method

The wells, containing submersible or turbine pumps, are usually installed outside the

work area at spacings of 20 to 200 ft (6-60 m). The well diameter can vary from 6 to 18 in.

(15-45 cm), and the screen is commonly of lengths from 20 to 75 ft (6-22.5 m). Often used

in combination with wellpoints as shown in

Figure 8.46,

the deep wells are installed

around the perimeter of the excavation and the wellpoints within the excavation.

Electro-osmosis

Application

Electro-osmosis is used to increase the strength of silts when they are encountered as thick

deposits in open excavations, slopes, or tunnels. It has been used infrequently in the