Environmental Engineering Reference

In-Depth Information

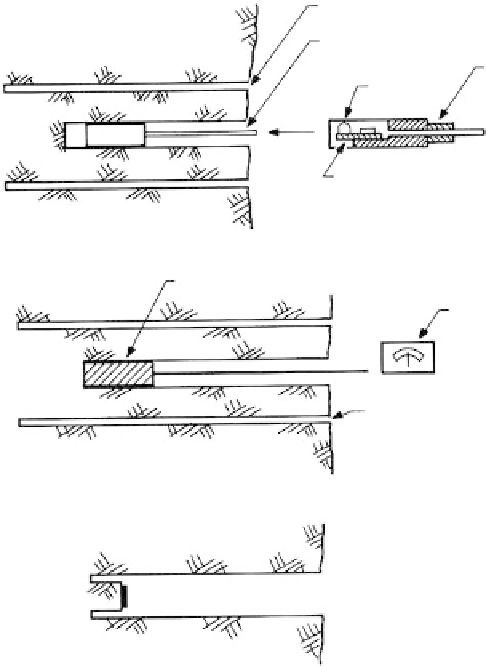

6-in. concentric borehole

1.5-in. borehole

Borehole

deformation

meter

Piston

Beryllium/copper

cantilever

(a)

Stress plug cemented to the wall of the hole

Stress-strain

measuring unit

connected to stress

plug

Trepanning hole to

relieve stresses

(b)

1

Set strain gage in

borehole with cement

Overcore borehole to

relieve stresses

1

2

2

(c)

FIGURE 4.33

Measurements of

in situ

stresses by stress relief in boreholes (a) borehole deformation meter; (b) high-modulus

stress plug or inclusion stress meter (a rigid or near-rigid device calibrated directly in terms of stress); (c)

Leeman “doorstopper” strain gage.

Procedure

The device is inserted into a small-diameter borehole (NX) and the stresses are relieved by

overcoring. These stresses are read directly with the inclusion stress meter, or computed

from strains measured with the deformation meter or strain gages. To compute stresses

when only strains are measured requires either a measurement or an assumption for the

rock modulus. Installation and interpretation are described by Roberts (1969). Maximum

applicable depths are of the order of 10 to 15 m because of the difficulties of making accu-

rate overcores, especially in holes that are not vertical.

Hydraulic Fracturing

Application

Hydraulic fracturing has been used to measure stresses in deep boreholes (Haimson, 1977)

and is still in the development stages.

Technique

A section of borehole is sealed off at the depth to be tested by means of two inflatable

packers. The section is pressurized hydraulically with drilling fluid until the surrounding