Environmental Engineering Reference

In-Depth Information

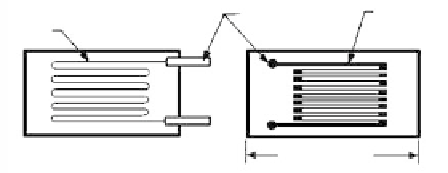

Fine-wire grid,

cemented to

backing

Lead-wire

attachments

Etched-metal

foil grid

FIGURE 4.1

Bonded resistance strain gages:

(a) wire grid, (b) foil grid.

Backing

1/16 to 6 in.

(a)

(b)

Unbonded, Encapsulated Gages

A fine wire is strung under tension over ceramic insulators mounted on a flexible metal

frame to form a resistance coil in unbonded, encapsulated gages

(Figure 4.2).

Usually two

coils are used and arranged so that one contracts while the other expands when the frame

is strained. The coils and the frame are factory-sealed into a tubular metal cover to provide

moisture protection. Mounting is achieved by bolting the gage to saddle brackets previ-

ously tack-welded or bolted to the measuring surface. The Carlson strain meter is one ver-

sion of the unbonded, encapsulated resistance gage.

Readouts

Strain indicators measure the resistance changes of the gages. They consist of a power sup-

ply, various fixed and variable resistors, a galvanometer, and a bridge circuit that can be

switched to connect the strain gages, resistors, and galvanometers in various configura-

tions.

Temperature Compensation

Temperature compensation is always required and can be achieved by a dummy gage

mounted so that it responds only to temperature-induced resistance changes or by the use

of self-compensating gages.

Vibrating-Wire Devices

Applications

Vibrating-wire devices are used for measurements of:

Strain with the transducer mounted on steel or embedded in concrete

●

Displacement and deformation with extensometers and joint meters

●

Tensile and compressive forces

●

Pore and joint water pressures

●

Changes in rock stresses

●

Changes in surface or subsurface inclinations

●

Temperature changes

●

Insulators

Fine wire

under tension

Lead-wire

attachment

FIGURE 4.2

Unbonded resistance strain gage. (From

Cording, E.J. et al., University of Illinois,

Urbana, Vols. 1 and 2, 1975. With

permission.)

Telescoping

tube with

bellows

8 to 20 in.