Environmental Engineering Reference

In-Depth Information

Procedures (ASTM D2435-02, D4186-98)

A specimen from an undisturbed clay sample is trimmed carefully into a rigid ring (brass

for most soils; Teflon for organic soils because of corrosion), and porous stones are placed

on top and bottom to permit vertical drainage. (A variation to permit horizontal drainage

uses a ring of porous stone and solid-end platens.)

The assembly is placed in a loading frame and subjected to a sequence of loads starting

initially with very small loads. Then (normally) the load is increased by doubling until the

test load significantly exceeds the anticipated field load, and the “virgin” compression

curve and preconsolidation stress (

p

c

) have been defined (Figure 3.78). Usually, three loads

beyond the range of

p

c

are required to define the virgin compression.

After the initial seating loading, the specimen is immersed in water to maintain satura-

tion (unless the clay is expansive, as will be discussed). Each load remains until pore pres-

sures are essentially dissipated and consolidation terminated; for most clays, 24 h is

adequate for each load cycle. When first applied, the load is carried by the pore water. As

water drains from the specimen, the voids close, the soil compresses, and the strength

increases until it is sufficient to support the load and the extrusion of water ceases. At this

point “primary compression” has terminated and the next load increment is applied (see

the discussion of secondary compression below.) Measurements are made and recorded

during the test of deflection vs. time for each load increment. (Plotting the data during the

test shows the experienced technician when full consolidation under a given load has

occurred, at which point, the next load is applied. This practice eliminates the need to wait

24 h between loadings. If pore-water pressures are measured, when they reach zero the

next load increment is applied.)

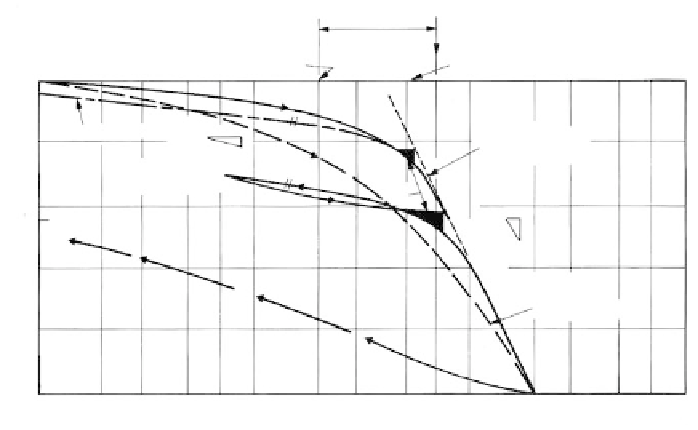

Pressure vs. Void Ratio Relationships

The total compression that has occurred after the application of each load is plotted to yield

a curve of either pressure vs. strain or pressure vs. void ratio (

e

-log

p

curve), where pres-

sure is plotted on a log scale, and strain or void ratio on an arithmetic scale (Figure 3.78).

p

f

∆

p

Overburden pressure p

o

Preconsolidation pressure P

c

e

a

Design curve

Undisturbed

sample curve

C

r

Unload

−

reload

cycle

"a"

e

f

C

c

Disturbed

sample curve

0.1

0.2

0.3

0.5

0.7

1.0

3

Pressure, tsf (log scale)

2

5

7

10

20

50

100

FIGURE 3.78

Consolidation test: pressure-void ratio curve (

e

-log

p

).