Environmental Engineering Reference

In-Depth Information

Mines, it was designed for near-surface or in-mine testing of coal and other fractured rocks

that are difficult to core. It has been used in all soft to medium-hard rocks.

Procedure

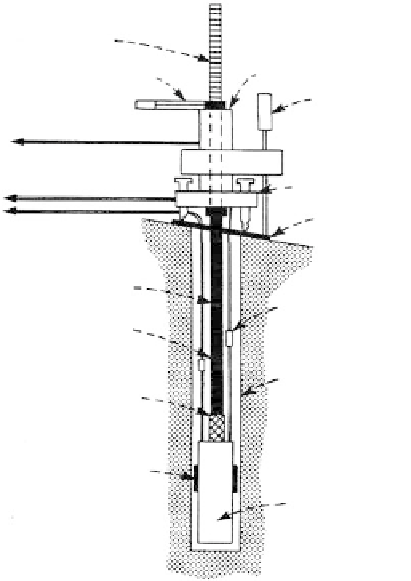

The apparatus is shown in

Figure 3.46.

A shear head, consisting of opposing plates with

two carbide teeth, is lowered into a 3 in. (75 mm) borehole. Normal stress is applied

by pushing the shear plates into the sides of the hole using a hand-operated pump.

The pressure is then valved off so it remains constant, while the same pump is used to

pull the expanded shear head a short distance upward along the hole by means of a hol-

low-ram jack. Both the expansion pressure and the pulling resistance are recorded, and

the test is repeated with different preselected normal stresses. Up to four tests can be con-

ducted at the same depth by rotating the shear head 45° between tests. A plot of each test

is made to obtain a Mohr's envelope of shear stress vs. normal stress providing meas-

urements of the angle of internal friction (

) and cohesion (

c

) (Handy et al., 1976).

Comparison with data from

in situ

direct shear tests indicate that cohesion values from

the BST are lower although the friction angles are close (R. L. Handy, personal commu-

nication, 2004).

φ

Applications

The apparatus is used in both rock (RBST) and soil (BST) in vertical, inclined, or horizon-

tal boreholes. The entire apparatus, including the shear head and pulling device, is easily

portable. A very significant advantage over other methods to measure shear strength is

that many tests can be run in a short interval of time, as many as ten per day, and yield

results on-site that can indicate if more tests are needed.

Threaded rod

Hollow jack

Dial gage

Half nut clamp

Shear hose

Retract hose

Tripod

Jack base

plate

Normal hose

Rod coupling

Hose connector

RW drill rod

NX hole

RW adapter

Shear plates

FIGURE 3.46

Schematic of borehole shear strength tester (BST) in

the borehole. (From USBM, Bureau of Mines, U.S.

Department of Interior, New Technology No. 122,

1981. With permission.)

BST body