Environmental Engineering Reference

In-Depth Information

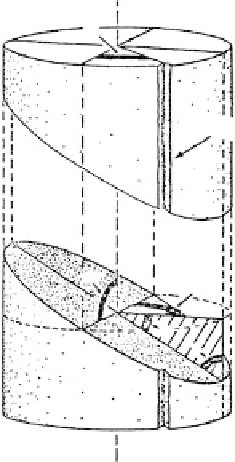

Scribe mark

Joint surface

90

°

90

°

δ

α

FIGURE 2.83

Oriented core with the joint surface intersecting the core wall at the joint

dip angle. The boundaries of a horizontal line across the joint are

located at angle ø providing the strike angle.

of 100% recovery with the orientation known. Defect orientation is an important factor in

rock-mass stability analysis.

Technique

1.

An NX-diameter hole or larger is drilled to where integral coring is to begin.

2.

A second, smaller hole (nominally about 1 in. [26 mm] in diameter) is drilled

coaxially with the first through the desired core depth, although usually not

exceeding 1.5 m in depth.

3.

A notched pipe is lowered into the hole and bonded to the rock mass with

cement or epoxy resin grout, which leaves the pipe through perforations.

4.

After the grout has set, a core is recovered by overcoring around the pipe and

through the cemented mass.

5.

During installation of the pipe, the notch positions are carefully controlled by a

special adapter and recorded so that when the core is retrieved, the orientation

of the fractures and shear zones in the rock mass are known.

Large-Diameter Cores by Calyx or Shot Drilling

Purpose

Calyx or shot drilling is intended to allow borehole inspection in rock masses in holes up

to 6 ft (2 m) in diameter.

Method

Calyx drilling uses chilled shot as a cutting medium. The shot is fed with water and lodges

around and partially embeds in a bit of soft steel. The flow of freshwater is regulated

carefully to remove the cuttings but not the shot. The cores are recovered by a special core-

lifter barrel, wedge pins, or mucking after removal of the core barrel. An example of a 36-

in.-diameter core taken in shale in which slickensides are apparent is shown in

Figure 6.54.

Limitations

The method is limited to rock of adequate hardness to resist erosion by the wash water and

to vertical or nearly vertical holes.