Environmental Engineering Reference

In-Depth Information

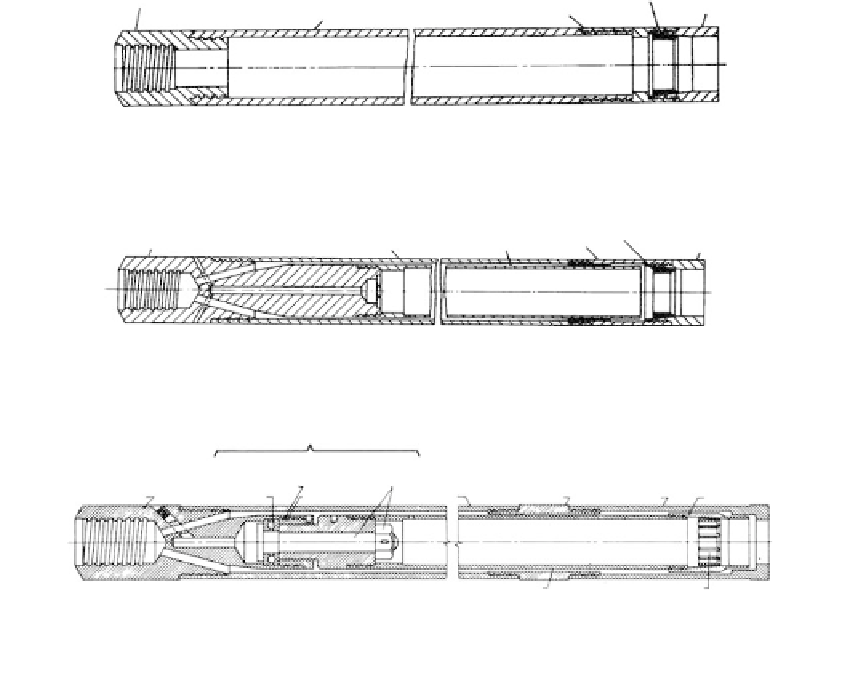

Core lifter

Core barrel head

Coring bit

Reaming shell

Core barrel

FIGURE 2.79

Single-tube core barrel. (Courtesy of Sprague and Henwood, Inc.)

Reaming

shell

Core lifter

Core barrel head

Outer tube

Inner tube

Coring bit

FIGURE 2.80

Rigid-type double-tube core barrel. (Courtesy of Sprague and Henwood, Inc.)

Hanger bearing assembly

Pin and

nut

Inner tube

head

Outer

tube

Core barrel head

outer

Bearing

retainer

Reaming

shell

Ball bearings

Blank bit

Lifter base

Inner tube

Core lifter

FIGURE 2.81

Swivel-type double-tube core barrel, series M. (Courtesy of Sprague and Henwood, Inc.)

Causes of Low Recovery

Rock conditions

: Fractured or decomposed rock and soft clayey seams cause low recovery,

for example, as shown in

Figure 2.78.

Rock quality can vary substantially for a given loca-

tion and rock types as illustrated in

Figuers 2.84

and

2.85,

which show a formation of gran-

ite gneiss, varying from sound and massive to jointed and seamy. Core recovery in the

heavily jointed zone is illustrated in

Figure 2.86.

Coring equipment

: Worn bits, improper rod sizes (too light), improper core barrel and bit,

and inadequate drilling machine size all result in low recovery. In one case, in the author's

experience, coring to depths of 30 to 50 m in a weathered to sound gneiss with light drill

rigs, light “A” rods, and NX double-tube core barrels resulted in 40 to 70% recoveries and

20 to 30% RQD values. When the same drillers redrilled the holes within a 1m distance

using heavier machines, “N” rod and HX core barrels, recovery increased to 90 to 100%

and RQDs to 70 to 80%, even in highly decomposed rock zones, layers of hard clay, and

seams of soft clay within the rock mass.

Coring procedure

: Inadequate drilling fluid quantities, increased fluid pressure, improper

drill rod pressure, or improper rotation speed all affect core recovery.

Integral Coring Method

Purpose

Integral coring is used to obtain representative cores in rock masses in which recovery is

difficult with normal techniques, and to reveal defects and discontinuities such as joint

openings and fillings, shear zones, and cavities. The method, developed by Dr. Manual

Rocha of Laboratorio Nacional de Engenheira Civil (LNEC) of Lisbon, can produce cores