Environmental Engineering Reference

In-Depth Information

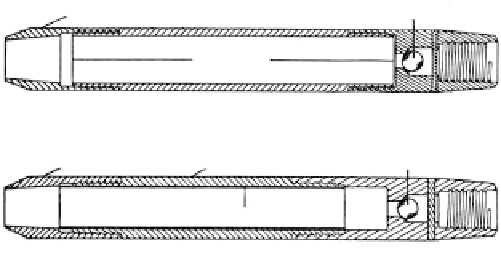

Hardened shoe

Ball check

Split tube

(a)

Hardened shoe

Outer split tube

Ball check

FIGURE 2.61

The split-barrel

sampler or split spoon

: (a)

without liner; (b) with liner. (Courtesy of

Sprague and Henwood, Inc.)

Thin wall liner

(b)

clays and fine cohesionless soils. Upon retrieval, the barrel between the head and the shoe

is split open

(Figure 2.62)

,

the sample is examined and described, removed, and stored.

In some sampler types, brass liners are used for procuring drive samples of strong cohe-

sive soils for laboratory direct-shear testing.

Sampling Procedure

The sampler is installed on the hole bottom, then driven into the soil with a hammer (nor-

mally 140 lb) falling on the drill rods. The number of blows required for a given weight

and drop height, and a given penetration, are recorded to provide a measure of soil com-

pactness or consistency as described in

Section 3.4.5

(Standard Penetration Test).

Thin-Wall Tube Samplers

Purpose

Thin-wall tube samplers are used to obtain UD of soft to stiff cohesive soils for laboratory

testing of strength, compressibility, and permeability.

Tube Materials

Cold-drawn, seamless steel tubing (trade name “Shelby tube”) is used for most soil mate-

rials; brass tubes are used for organic soils where corrosion resistance is required. Wall

thickness is usually 18 gage; heavier gages are available. Lacquer coating can provide cor-

rosion protection and reduce internal frictional resistance and sample disturbance.

Tube diameters and lengths range from 2 to 6 in. in diameter, 24 to 30 in. in length. Tubes

2 in. in diameter are used in 2½ in. exploratory borings, but 2 in. diameter samples have a

large ratio of perimeter disturbance to area and are considered too small for reliable labo-

ratory engineering-property testing.

Tubes 3 in. (2.87

) in diameter are generally considered the standard type for laboratory

test samples. The tube should be provided with a cutting edge drawn in to provide about

0.04 in. inside clearance (or 0.5 to 1.5% less than the tube I.D.), which permits the sample

to expand slightly upon entering the tube, thereby relieving sample friction along the

walls and reducing disturbance.

Tubes 4 to 6 in. in diameter reduce disturbance but require more costly borings. A 5 in.

tube yields four samples of 1 in. diameter from the same depth for triaxial testing.

Operations

Thin-wall tubes are normally pressed into the soil by hydraulically applied force. After

pressing, the sample is left to rest in the ground for 2 to 3 min to permit slight expansion