Environmental Engineering Reference

In-Depth Information

Rock conditions, since various combinations of rock bits and core barrels are

used, depending on rock type and quality and the amount of recovery required.

●

Surface conditions, which vary from land or quiet water to shallow or deep

water with moderate to heavy swells.

●

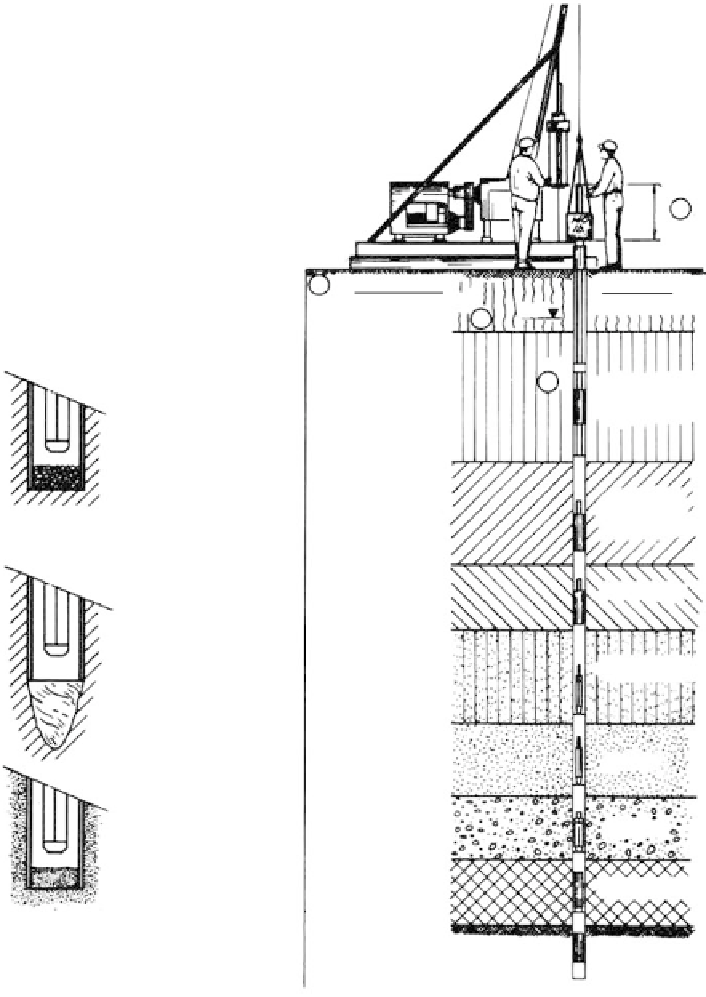

Some common sampling tools and their applications to various subsurface conditions

are illustrated in Figure 2.60. The various tools and methods and their applications and

limitations are described in

Table 2.16.

Inspection is provided

to control

1. Correct driving energy

2. Sampler type

3. Sampler condition

4. Sampling sequence

5. Sample identification

6. Sample preservation

7. Condition at sampling depth

1

Sampler type

Splitbarrel (2-1/2" ID)

2

Soil profile

cinder fill

BWL

8

7

Piston

Organic silt

or soft clay

Sampler dropping on

gravel or cinders not

cleaned from casing,

results in high blow

count

Firm to

stiff cloy

Shelby tube

Denison

coreborrel

Hard clay

Soils loosened by

overwashing. Blow

count will be lower

than true count

Piston or

splitbarrel

(1-3/8" ID)

Silty Sand

splitbarrel

(1-3/8" ID)

Sand

splitbarrel

(2-1/2" ID)

Sand under

hydrostatic pressure

plugging casing. Blow

count will be higher

than true

Gravel

Corebarrel-

carboloy bit

Soft rock

8. Groundwater measurements

9. Depth of boring

10. Sample recovery

−

percentage

Hard rock

Corebarrel-

diamond bit

FIGURE 2.60

Common sampling tools for soil and rock and their application.