Environmental Engineering Reference

In-Depth Information

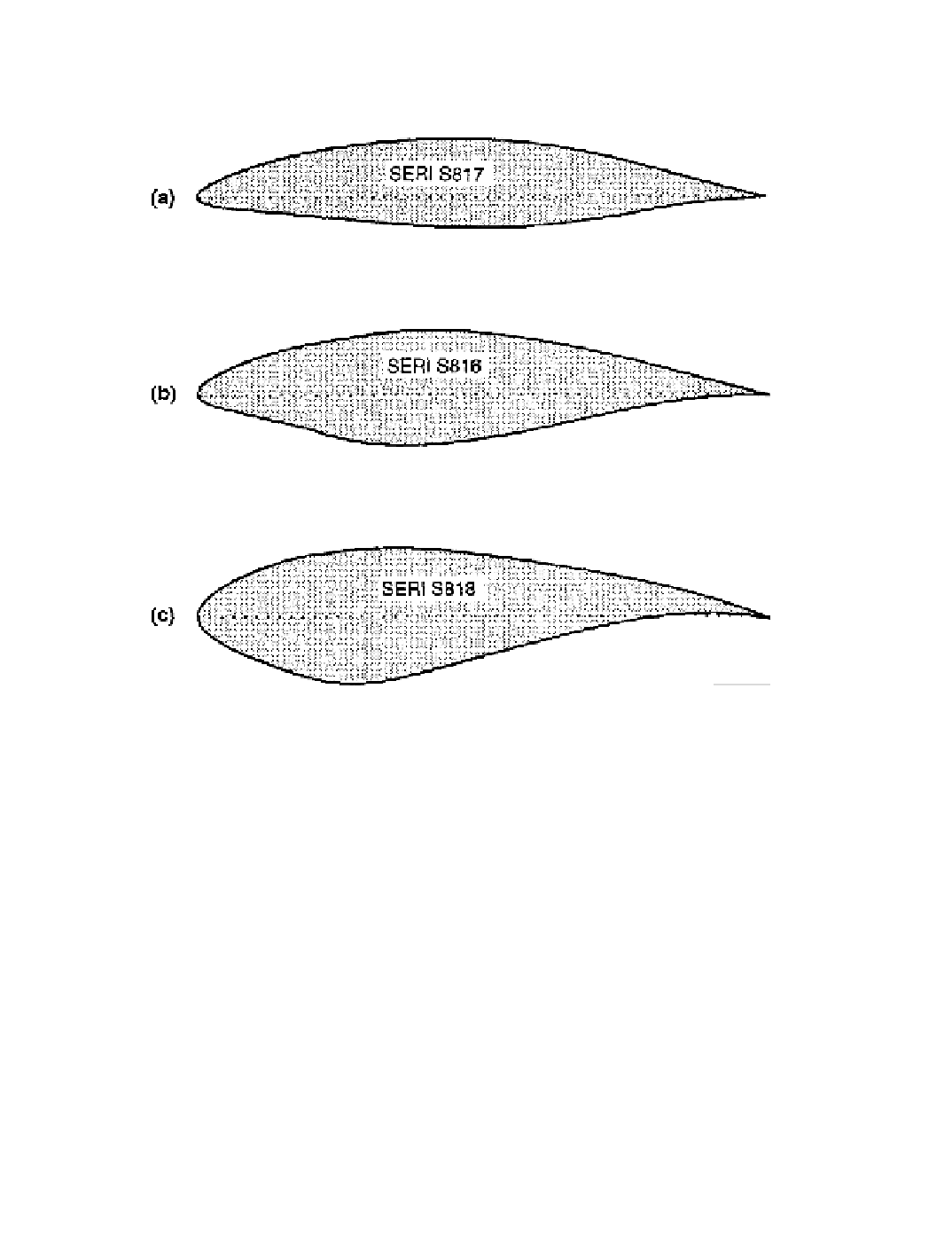

Figure 6-9. Contours of the SERI series of airfoils designed specifically for fixed-pitch

HAWTs 36 m in diameter and larger.

(a) Tip region (

r/R

» 0.95) (b) Primary outboard

airfoil (

r/R

» 0.75) (c) Root region (

r/R

» 0.40) [Tangler and Somers 1995]

Field Performance Testing of Wind Turbine Airfoils

While idealized, two-dimensional wind tunnel tests are necessary for developing airfoil

contours and obtaining lift and drag data with which to predict rotor power output, final

evaluation of a wind turbine airfoil must be made on the basis of full-scale field

performance tests. Only in the field can the combined effects of spatial and temporal

turbulence, variability in steady wind speed, airfoil rotation, hub/tip losses, surface

roughness, and manufacturing tolerances be measured. Of course, the variability of the

wind complicates the testing, and airfoil-to-airfoil comparisons are more difficult to make.

Standardized procedures have therefore been developed for the purpose of increasing the

reliability and reducing the uncertainty in field tests of wind turbine performance,

emphasizing

power

curves

[AWEA 1988] and

energy output

[ASME 1988].

Search WWH ::

Custom Search