Environmental Engineering Reference

In-Depth Information

is not of the same importance as it is for aircraft wing design. General analysis of rotor

performance shows that the primary factor is the product of the chord and the lift

coefficient, or

cC

L

.

Thus, when other characteristics like tip-speed ratio and diameter are

held constant, operating at a higher lift coefficient will permit the use of narrower blades.

Generally, this will not result in lower viscous power losses, since viscous torque is

controlled more by the L/D ratio of the airfoil than the actual value of lift.

The principal factor controlling the lift-to-drag ratio of a given airfoil section is the

Reynolds number. Since a smaller chord reduces Reynolds number in accordance with

Equation 6-1, this is an aerodynamic reason to avoid narrow-chord blades. Another factor

relating to the use of narrower blades is the negative effect on structural stiffness, which

reduces rapidly as thickness decreases. Stiffness is approximately proportional to the square

or the cube of the thickness, and thickness is proportional to the chord.

Drag coefficient is of limited importance in determining turbine performance in the

usual operating range of wind speeds and at normal tip-speed ratios. Generally, its effect

on the power coefficient varies directly with the cube of the tip-speed ratio. When this ratio

is high (in excess of 10, typically) the drag coefficient does become somewhat more

significant. This situation occurs in lower wind ranges when it may be more important to

maximize energy extraction.

Surface Roughness Effects

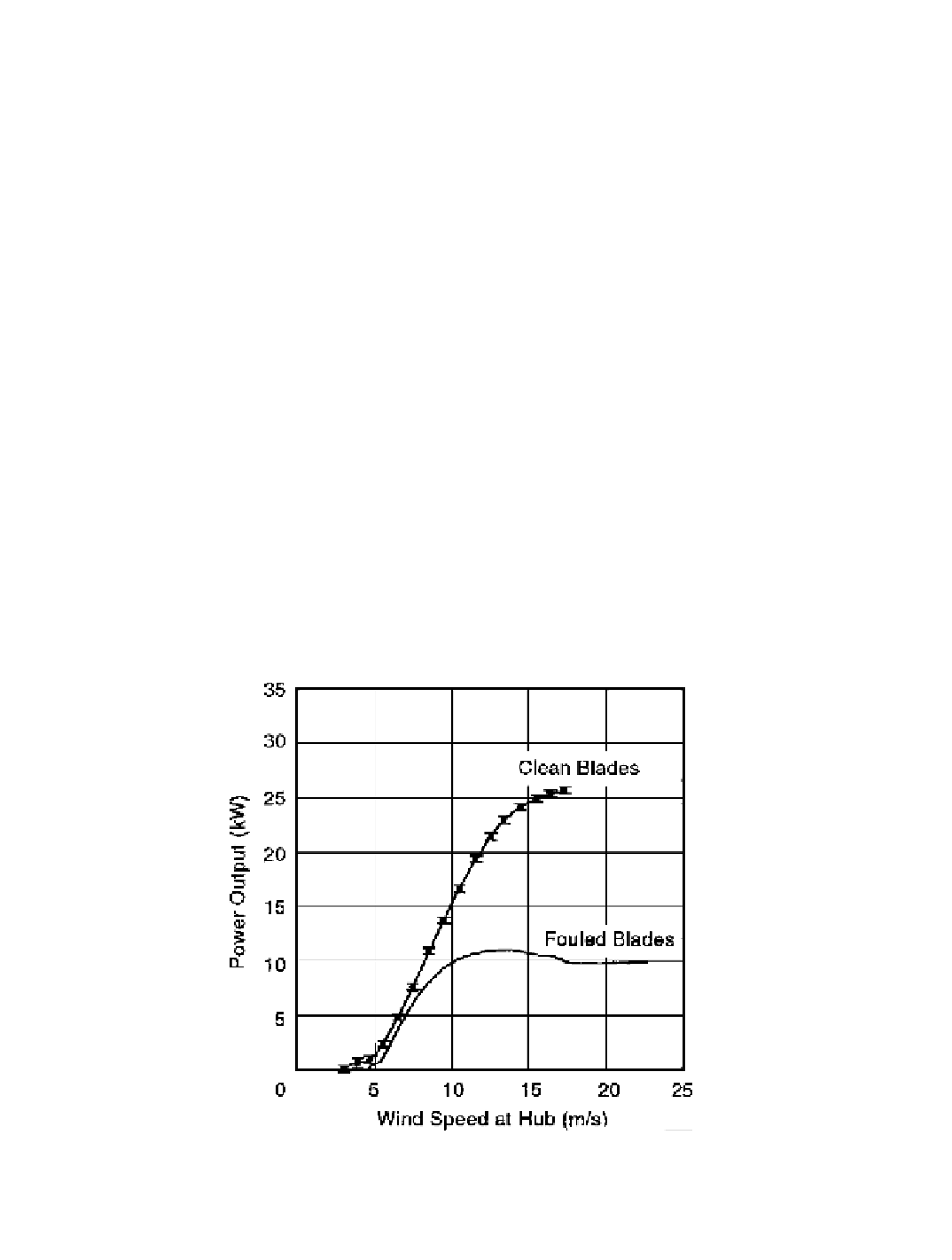

An important operating requirement that relates to a wind turbine airfoil is its ability

to perform when the smoothness of its surfaces has been degraded by dust, dirt, rain, or

insect debris. Field experience with small- and medium-scale units has indicated that very

severe performance degradation can occur in these circumstances. Figure 6-5 shows field

test power curves for a small-scale (10-m dia.) HAWT with both clean and dirty blades.

It appears that this deleterious effect is most pronounced in fixed-pitch stall-controlled

Figure 6-5. Effect of blade fouling by dust, dirt, and insects on the performance of a

small-scale HAWT 10-m in diameter.

Search WWH ::

Custom Search