Environmental Engineering Reference

In-Depth Information

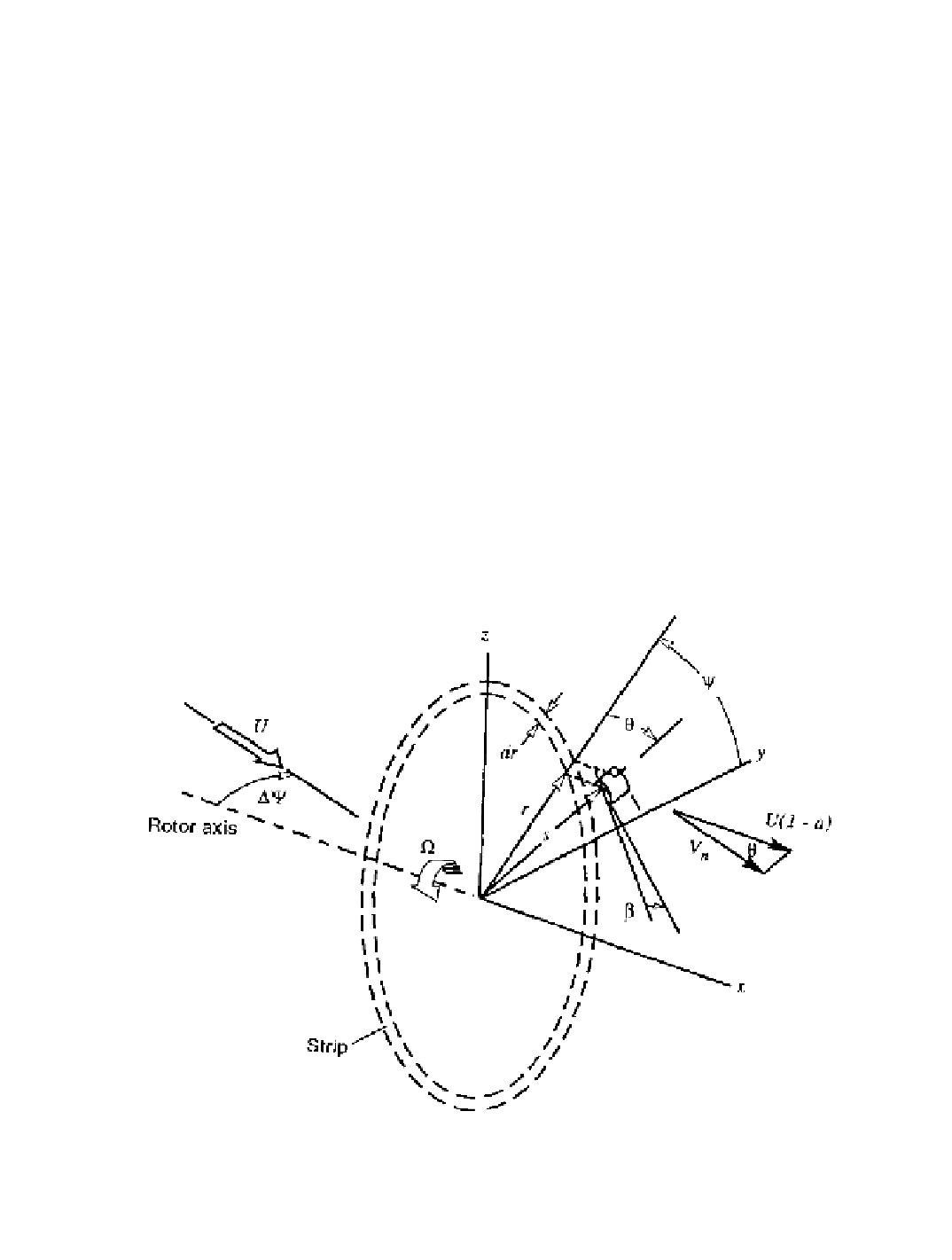

Flow Model

The foremost assumption in strip theory is that individual

streamtubes

or

strips

(the

intersection of a streamtube and the surface swept by the blades) can be analyzed indepen-

dently of the rest of the flow. Such an assumption works well for cases where the circulation

distribution over the blade is relatively uniform, so that most of the vorticity is shed at the

blade root and the blade tip. The deployment of

control surfaces

, however, can violate this

assumption. For example, the use of

partial-span pitch control

on a HAWT rotor introduces

discontinuities in circulation, and appreciable vorticity can be shed near the junction between

the inboard blade and the moveable tip. Fortunately, control surfaces are usually deployed

to spill excess power at high wind speeds, when the induced velocity is relatively small.

Thus, calculation errors that arise when strip theory methods are used to analyze rotors with

deployed control surfaces are not usually significant.

A second assumption associated with the development of strip theory is that

spanwise

flow

is negligible, and therefore airfoil data taken from two-dimensional section tests are ac-

ceptable. Strip theory does not predict any induced flows along the blades. However, when

a blade is not perpendicular to the axis of rotation (

e.g.

, when the blade has a

coning angle

)

the wind has a component that is directed along the span of the blade. This component is

neglected and two-dimensional flow is assumed, adding some error to the airfoil data. A

third assumption is that flow conditions do not vary in the circumferential direction. With

this assumption, the “strip” to be analyzed is a uniform annular ring centered on the axis of

revolution.

Figure 5-12 shows the strip geometry and the coordinate system used. Note that the

coordinate

s

is measured along the blade and

r

is at right angles to the rotor axis. The wind

velocity,

U

, is assumed to be constant in time and space and aligned with the axis of rotation,

so that the

yaw error

, DY, is zero. When the rotor blades are coned, the velocity diagram in

Figure 5-12. Strip geometry and coordinate system.

Search WWH ::

Custom Search