Environmental Engineering Reference

In-Depth Information

machines to continuously and slowly oscillate plus or minus 0 to 5 deg around the opti-

mum rotor orientation.

Tower and Foundation

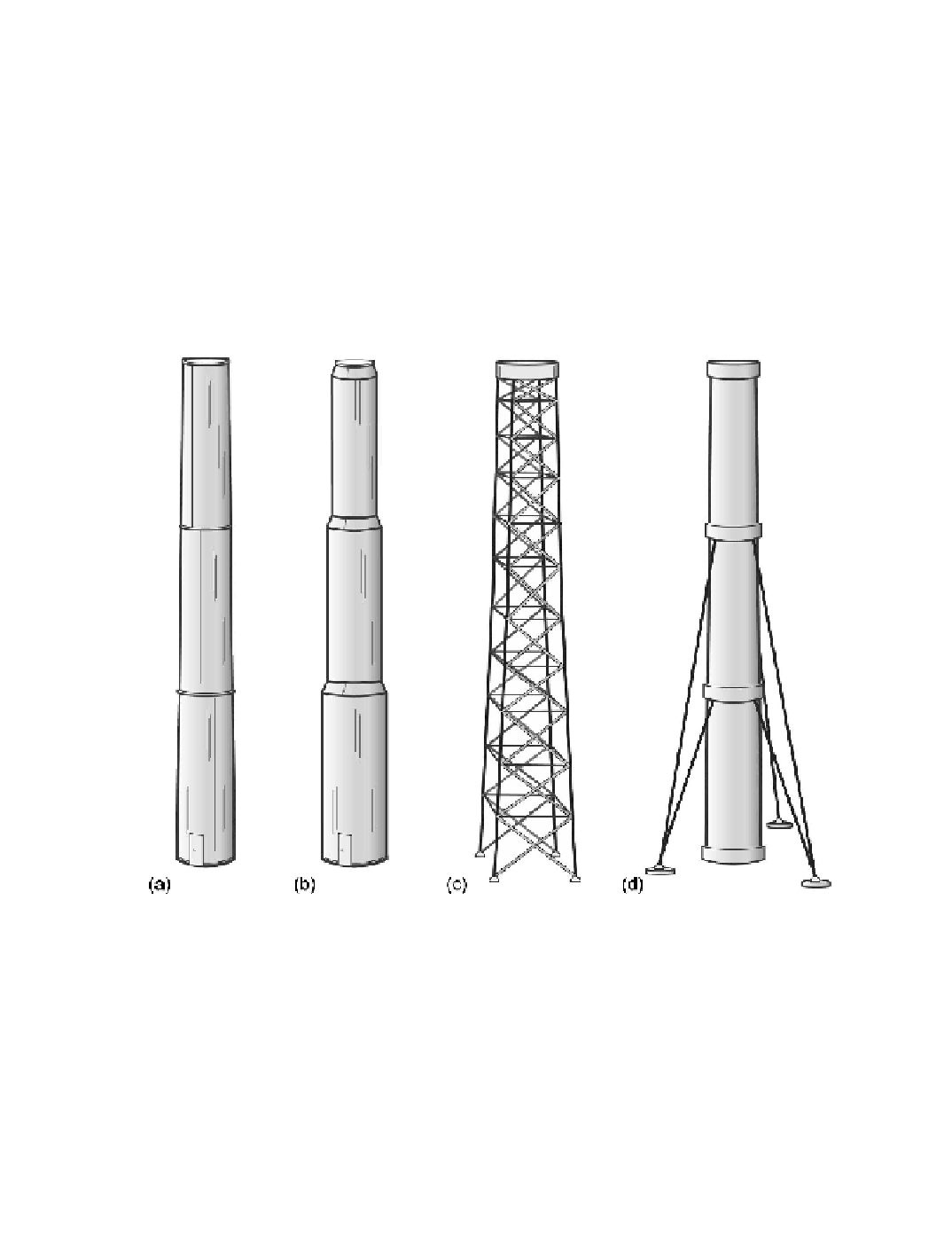

Figure 4-4 shows some of the many configurations of wind turbine towers that have

been tried in the past, such as tapered tubular shells, stepped tubular shells, trusses, and guyed

shells. Today, the vast majority of towers for large- and medium-scale commercial wind

turbines use cylindrical and tapered tubular shells made of rolled steel plates and configured

as free-standing

monopoles

(see Figs. 4- to 4-4). A concrete foundation is typically custom

designed for these towers based on the soil conditions at the site. Tower heights normally

range from 40 m up to more than 60 m. Towers are often manufactured as close to the site

as possible to reduce transportation and logistics costs.

Figure 4-4. Typical HAWT tower configurations.

(a) Tubular shell (b) Stepped shell (c)

Truss (or lattice) (d) Guyed shell (or, similarly, guyed truss)

The expertise for manufacturing steel shell towers is widely available, although the

thickness of the steel plates and the diameter of the sections for large-scale towers some-

times exceed the limits of local rolling facilities. Concrete is being used more frequently in

the lower sections of larger towers, to mitigate high steel prices and transportation limits.

Enercon

, builder of some of the largest wind turbines in the world, is using pre-cast concrete

towers.

Search WWH ::

Custom Search