Environmental Engineering Reference

In-Depth Information

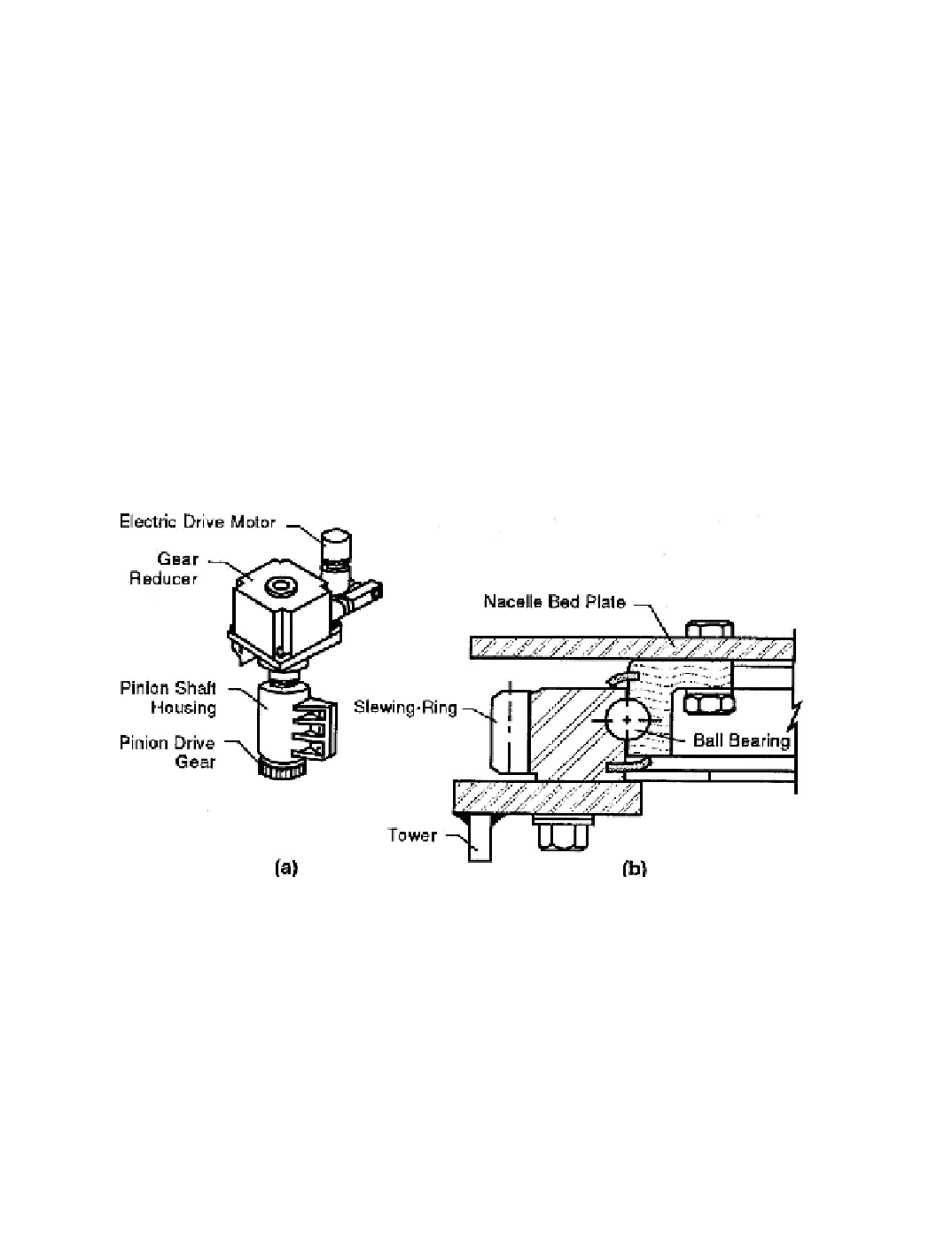

Yaw drive system

All HAWTs are designed to track the wind by orienting the nacelle in

azimuth

(compass

direction) so that the rotor plane is normal to the wind. Most HAWTs with upwind rotors

use an active yaw system for wind alignment. Almost all downwind machines use

weather

vaning

or

passive yaw

for tracking the wind. Many small wind turbine rotors are located

upwind of the tower and track the wind through the action of wind forces acting on a tail

vane. Passive yaw systems reduce cost, weight, and maintenance by eliminating yaw drive

components. However, if not properly designed, passive yaw can result in higher fatigue

loads caused by operations at relatively large

yaw errors

The majority of yaw drive systems for medium- and large-scale upwind machines are

electromechanical, with the remainder being predominantly hydraulic. Figure 4-3(a) il-

lustrates a common yaw drive system in which a motor turns a small

pinion gear

through a

worm-gear reducer

. These components are mounted on the movable bedplate of the nacelle.

The pinion gear engages a large, stationary

slewing-ring

or

bull gear

mounted rigidly on the

tower, as illustrated in Figure 4-3(b). The tower structure provides the stiff vertical support

required for the yaw bearing. As turbine sizes have increased, so have tower heights and

diameters, yielding larger diameters and costs of yaw bearings. These very large diameters

are pushing the capability of machining yaw bearings, putting pressure on the manufacturing

supply chain for large-scale wind turbines.

Figure 4-3. Schematic diagram of a motor-driven yaw system.

(a) Electric or hydraulic

motor drive and pinion gear (b) Bull gear and yaw bearing assembly.

Upwind machines have experienced fatigue-related problems with yaw slew rings and

the pinion drives. Most of these result from unbalanced rotors and underestimating wind

loads from turbulence and wind shear, both horizontal and vertical.

Yaw damping

, either by

the use of sliding

yaw

brakes

or flexible drive mechanisms, has proven beneficial in reduc-

ing yaw slewing rates and cyclic loads in all sizes of HAWTs. The problems that have been

encountered most frequently with downwind machines are associated with

hunting

, which

causes premature wear of yaw drives and bearings. Hunting refers to the tendency of some

Search WWH ::

Custom Search