Environmental Engineering Reference

In-Depth Information

Sweden

Sweden proceeded rapidly

into a large-scale turbine research

program, after irst experimenting

with the

SAAB-Scania 100-kW

HAWT

, which was tested near

Uppsala. A Swedish consortium

named

KaMeWa

developed a 2.5-

MW, 75-m diameter turbine with

two blades on a rigid hub upwind

of the tower, and installed it at

Nasudden on the island of Gotland.

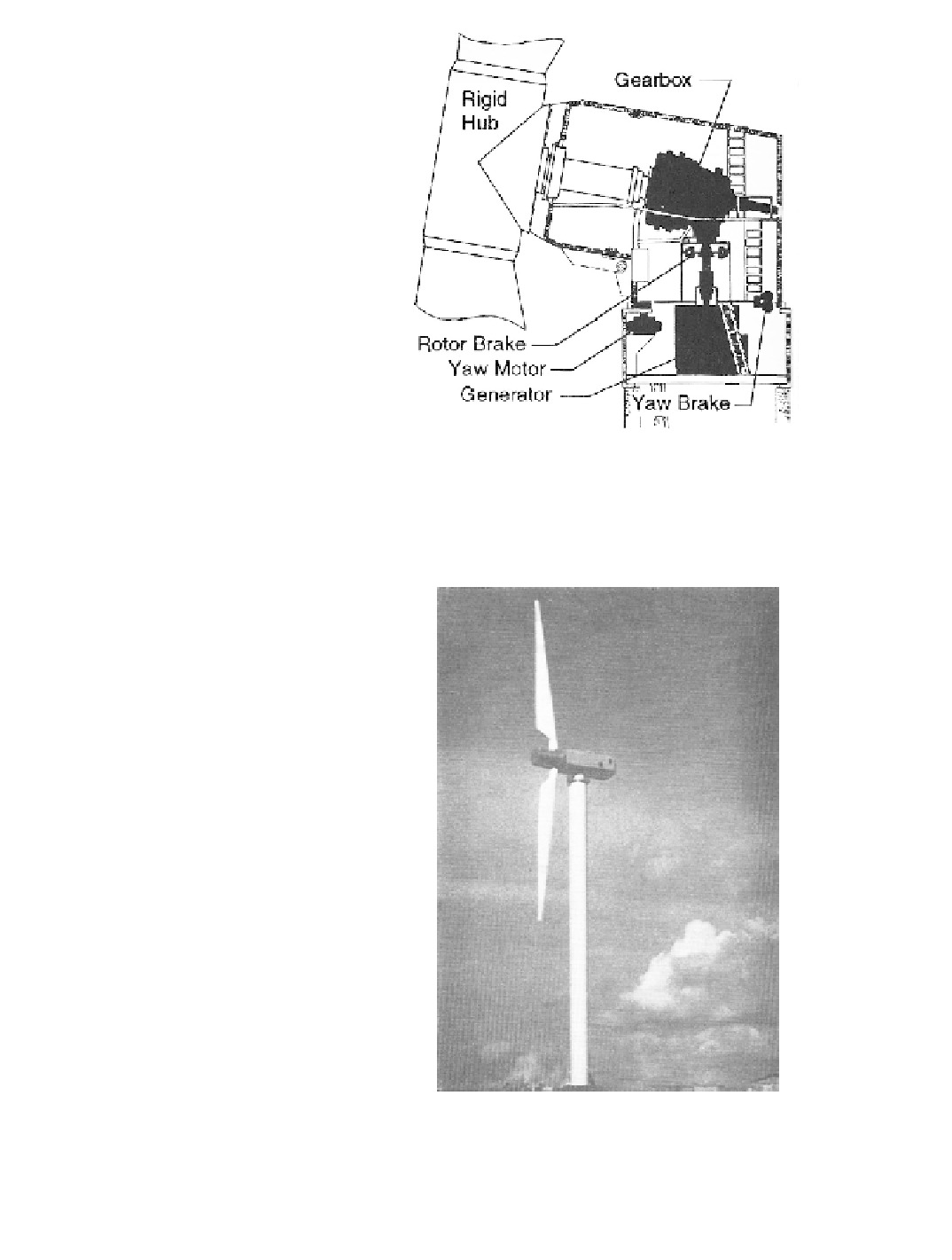

The

KaMeWa HAWT

contained two

unusual features: As shown in

Figure 3-33, the last stage of the

gearbox utilized bevel gears to

drive its generator. This component

was mounted vertically in the tower

just below the nacelle, thus elim-

inating the need for power slip-

rings. A second unusual feature

was a carriage assembly mounted

on vertical rails on the side of the

concrete cylindrical tower, for

raising or lowering all major com-

ponents (including the nacelle with

rotor blades mounted). This elimi-

nated the need for a large crane

during construction or maintenance.

The second Swedish turbine

was designed as a joint venture

between Karlskronavarvet (KKRV)

in Sweden and

Hamilton Standard

in the U.S. Called the

WTS-3

, it

was built at Maglarp, near Malmo

in southern Sweden (Fig. 3-34).

Although more conventional than

the KaMeWA design, the 3-MW

WTS-3 was nonetheless techno-

logically advanced. It had a tall,

“soft-soft” tower and a two-bladed,

teetered, downwind rotor 78-m in

diameter. Its gearbox was mounted

on springs to absorb dynamic

torques. The iberglass blades of

the WTS-3 were designed by

engineers at Hamilton-Standard

and fabricated on a specially-built

and automated ilament-winding

machine.

Figure 3-33. The unique drive train in the

2.5-MW KaMeWa HAWT eliminated sliprings

to carry power from the generator. (

Courtesy of

the National Energy Administration, Sweden

)

Figure 3-34. The 3-MW WTS-3 HAWT near

Maglarp, Sweden.

(

Courtesy of Hamilton Standard

)

Search WWH ::

Custom Search