Environmental Engineering Reference

In-Depth Information

issues could have remained unidentiied if the wind turbine rating was an extremely small

percentage of the local generating capacity.

The irst unit was fabricated at NASA Lewis, while a parallel contract was awarded to

Westinghouse Electric Corporation

to construct the remainder. While ostensibly identical,

each machine received detailed improvements based on the experiences of the prior

installation. The

Lockheed Corporation

, which had built the original fabricated-aluminum

blades for the Mod-0, provided the initial sets of Mod-0A blades to the same general design

but with thicker skin panels. However, the downwind coniguration and rigid hub intro-

duced high and (at that time) uncertain dynamic loads that caused fatigue cracks in the

aluminum skins and ribs near the blade roots. Eventually all four rotors were itted with

laminated wood-epoxy or iberglass blades and operated successfully for extended periods.

Probably the most severe operational test of the Mod-0A came in the installation at

Block Island, which was one of the reasons for the selection of that site. The Block Island

grid is powered by several diesel-electric generators and is not interconnected with any

other utility. Block Island has many summer vacationers and only a very small year-round

population. Thus, summer peak loads reach over 1,800 kW, while during night hours in

winter (which is also the high-wind season) the total load can go down to only a few

hundred kilowatts. Occasionally the Mod-0A at 200 kW was producing over 50 percent of

the power for the island. This large penetration introduced several problems in terms of

both

voltage and frequency stability

and diesel operating problems caused by excessive

throttling. The Block Island Mod-0A was therefore derated to 150 kW during winter opera-

tions, unless under special test.

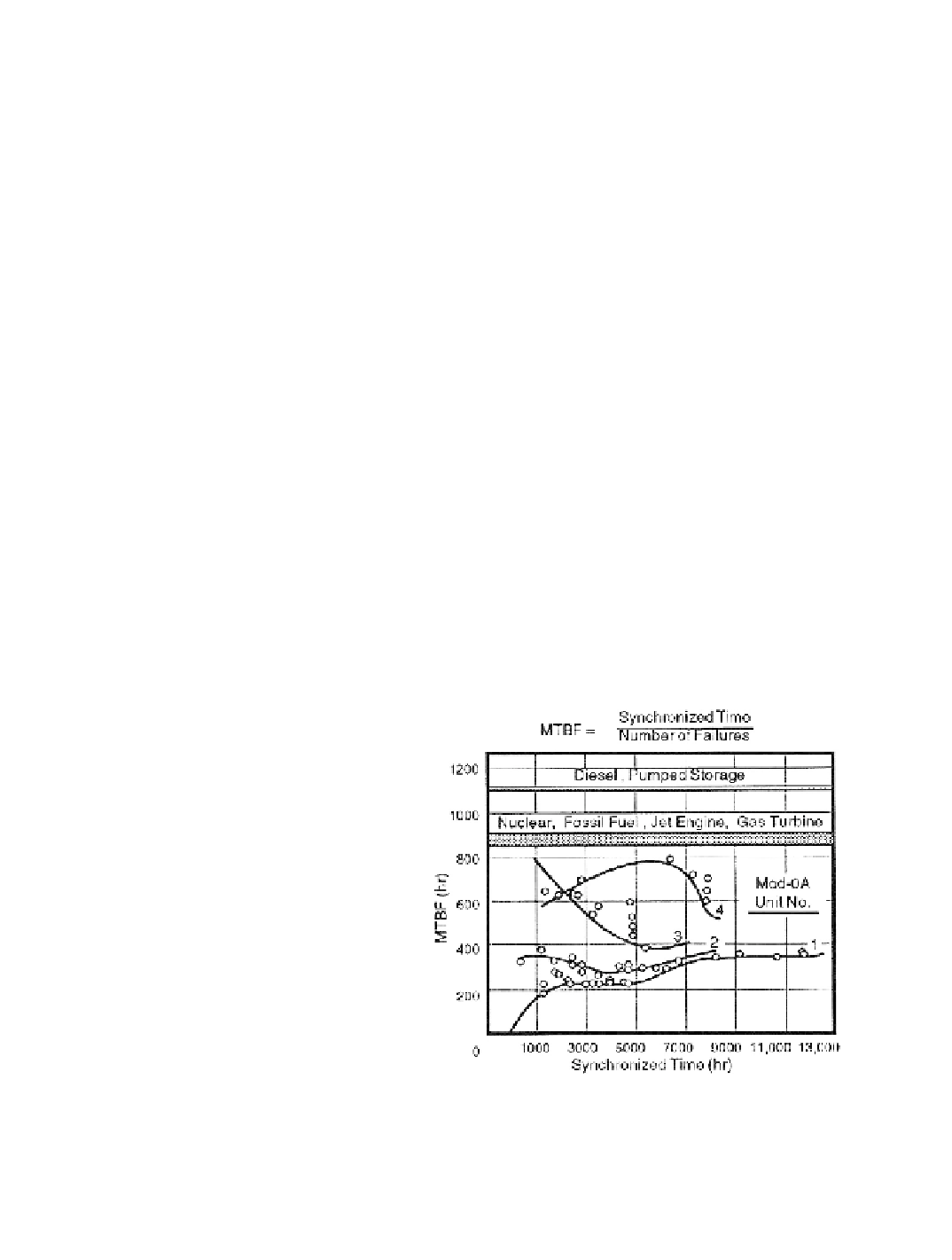

When the Mod-0A project was completed in June 1982, the four machines had

accumulated over 38,000 hours of operating time and had fed some 3.6 million kWh into

their host utility grids [Shaltens and Birchenough 1983]. At a

Hawaiian Electric Company

site near Kahuku, the fourth and most reliable Mod-0A (Fig. 3-30) achieved a

capacity

factor

of 0.48 during its last months of operation and was a principal cause of the devel-

oping interest in wind power in the Hawaiian Islands. The highly successful operation of

the Kahuku turbine also led its builder, the Westinghouse Corporation, to privately develop

a 600-kW HAWT and Hawaiian Electric Industries (the parent corporation of the utility)

to participate in the later Mod-5B

program and encourage private

wind power developers. The most

important contribution of the four

Mod-0A HAWTs was that they

produced the irst visible evidence

that wind turbines, while not yet

cost-effective, could be success-

fully integrated into a utility's

normal operations and could pro-

duce high-quality AC power of

value to that utility. They also

provided a technology base that

paved the way for the growth in

size of privately-developed wind

turbines, from the 10- to 15-m

diameter and 10- to 25-kW sizes

of the early 1970s to the 100- to

300-kW and 20- to 30-m diameter

turbines that were developed and

installed in the late 1980s.

Figure 3-30. Mod-0A mean times between failure.

Unit No. 4, on Oahu in the Hawaiian Islands, was the

most durable.

[Shaltens and Birchenough 1983]

Search WWH ::

Custom Search