Environmental Engineering Reference

In-Depth Information

Vertical Axis Systems

Several vertical-axis concepts have been proposed for wind turbines that are driven by

lift forces, rather than the drag forces that turn a panemone. These include the

Darrieus

rotor

which has been the most successful, and this VAWT coniguration is discussed in the

following section. The

giromill

, another lift-driven vertical-axis machine, has been deve-

loped by several manufacturers. Giromills use straight vertical blades whose pitch angles

vary cyclically during rotation and are independently controlled. The 40-kW prototype built

and tested by the

McDonnell Aircraft Company

was discussed previously (Fig. 3-15). The

mechanical complexity of the blade support and pitch-change systems has usually prevented

giromill designs from being cost-effective.

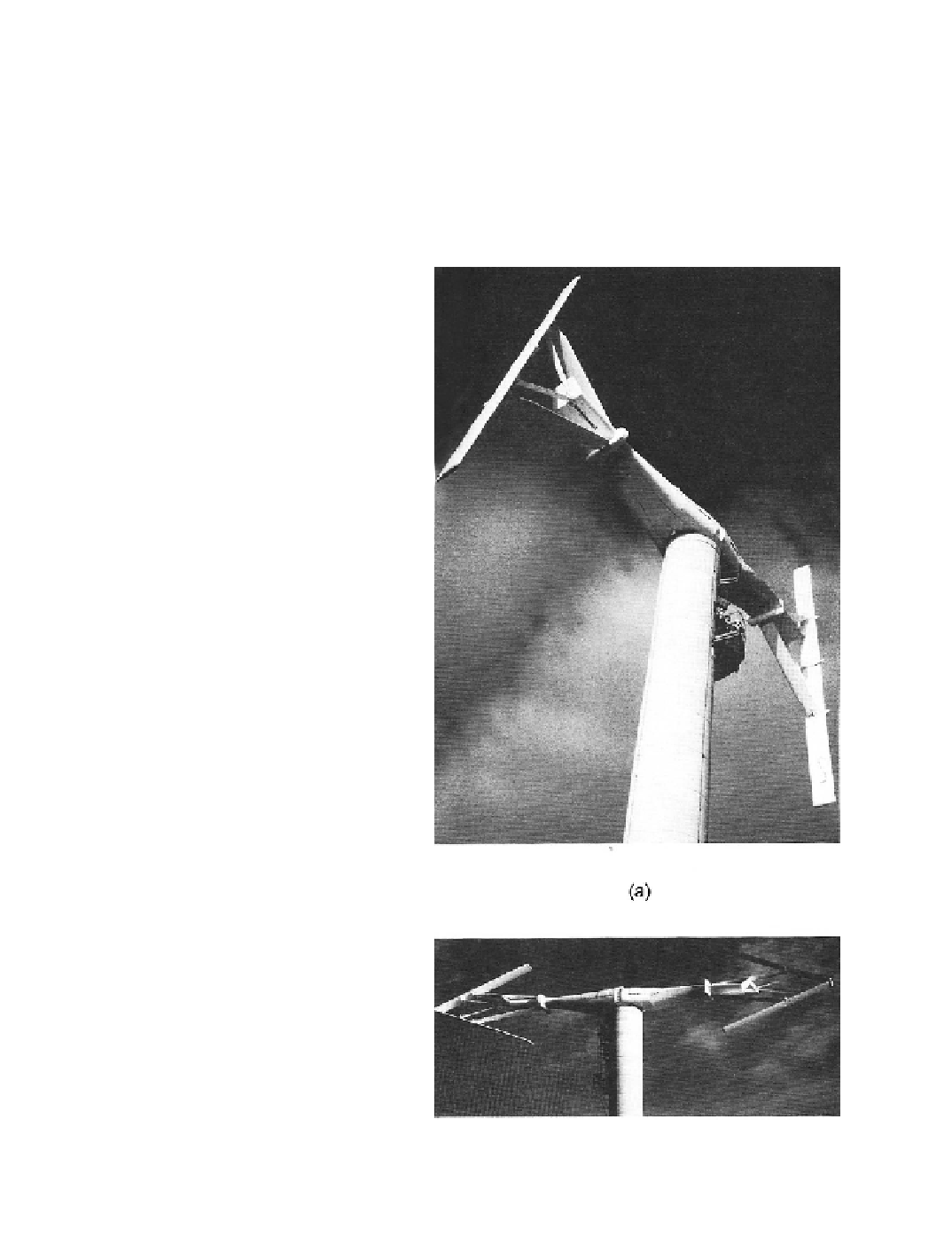

An innovative VAWT rotor,

invented by Peter Musgrove at

Reading University in England,

is the

Arrow

coniguration

shown in Figure 3-18. This

prototype at Carmarthen Bay,

South Wales, is 25 m in

diameter and rated at 130 kW

[Musgrove and Clare 1987]. Its

vertical turbine shaft and a

horizontal crossarm form a

rotating “T”. Two blades are

attached to the ends of the

crossarm by struts, and each is

hinged at its mid-length. Below

the rated wind speed the blades

are vertical, but at wind speeds

above rated they are furled or

“reefed” to an arrow-head shape

by hydraulic actuators in the

crossarm. This reduces their

swept area and limits both the

output power and blade loads.

Figure 3-18. The 125-kW,

25-m diameter Musgrove

Arrow VAWT at Carmarthen

Bay, South Wales.

(a) Blades

vertical for maximum swept

area (b) Blades furled.

(Courtesy of

Vertical Axis Wind

Turbines Ltd.

)

(b)

Search WWH ::

Custom Search