Environmental Engineering Reference

In-Depth Information

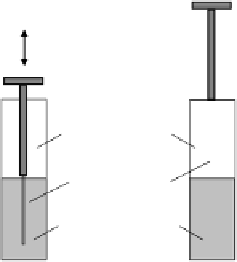

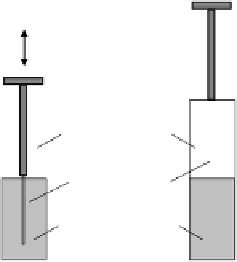

unique features of SPME make it an ideal tool by combining sampling, extraction,

concentration, and injection into a single process. SPME can be used directly for

both liquid and gas samples (Fig. 7.9).

(a)

(b)

Headspace

SPME fiber

Liquid sample

Figure 7.9

Two types of SPME applications in (a)

liquid samples, and (b) headspace samples

The main principle of SPME operation is based on the partitioning of analytes

between an aqueous (vapor) sample and a stationary phase on the fiber (f). The

amount of analyte adsorbed by the coating at equilibrium is described by:

K

fs

V

f

C

0

V

s

K

fs

V

f

þV

s

m ¼

ð7

:

12Þ

where m is the mass of analyte adsorbed by coating, C

0

the initial analyte

concentration in sample, K

fs

the partition coefficient for analyte between coating and

sample matrix, V

f

the volume of coating, and V

s

the volume of sample. Eq. 7.12

indicates that the adsorption is proportional to the partition coefficient (hence the

hydrophobicity of analyte), and the initial analyte concentration. The adsorption is

also related to the sample volume and coating volume. However, if sample volume

(V

s

) is very large, this equation becomes:

m ¼ K

fs

V

f

C

0

13Þ

The above equation indicates the independence of adsorption on sample volume,

which is an added advantage for SPME, because SPME can be simply exposed to air

or dipped into water without measuring the sample volume.

ð7

:

7.3.4 Soxhlet and Automatic Soxhlet Extraction

(Soxtec)

Soxhlet extraction was developed in 1879 by Franz von Soxhlet initially for the

extraction of lipid from a solid test material. It can be used for any solid samples and

its environmental applications are mainly for the extraction of SVOCs from solid

Search WWH ::

Custom Search