Environmental Engineering Reference

In-Depth Information

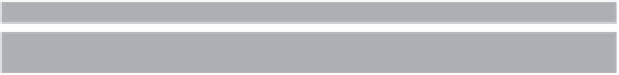

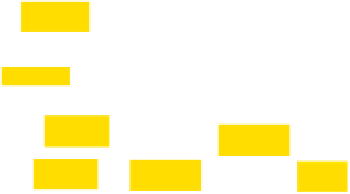

Reverse

Reverse

Osmosis

Utrafiltration

Particle filtration

Separation

Process

Osmosis

Microfiltration

Nanofiltration

Aqueous

Salt

Whole

Broth Cells

E-Coat Pigment

Milk Proteins

Red Blood Cells

Relative

Size of

Common

Materials

Gelatin

Fat Micelles

Bacteria

Metal Ion

Endotoxin Pyrogen

Activated

Carbon

Oil Emulsions

Synthetic

Dyes

Lactose

(Sugars)

Virus

Blue

Indigo Dye

Cryptosporidium

Colloidal

Silica

Giardia

Cyst

Human Hair

Microns 0.001 0.01 0.1 1.0 10 100 1000

Approx Molecular

Weight

100 200 1,000 20,000 100,000 500,000 1 MM 5 MM

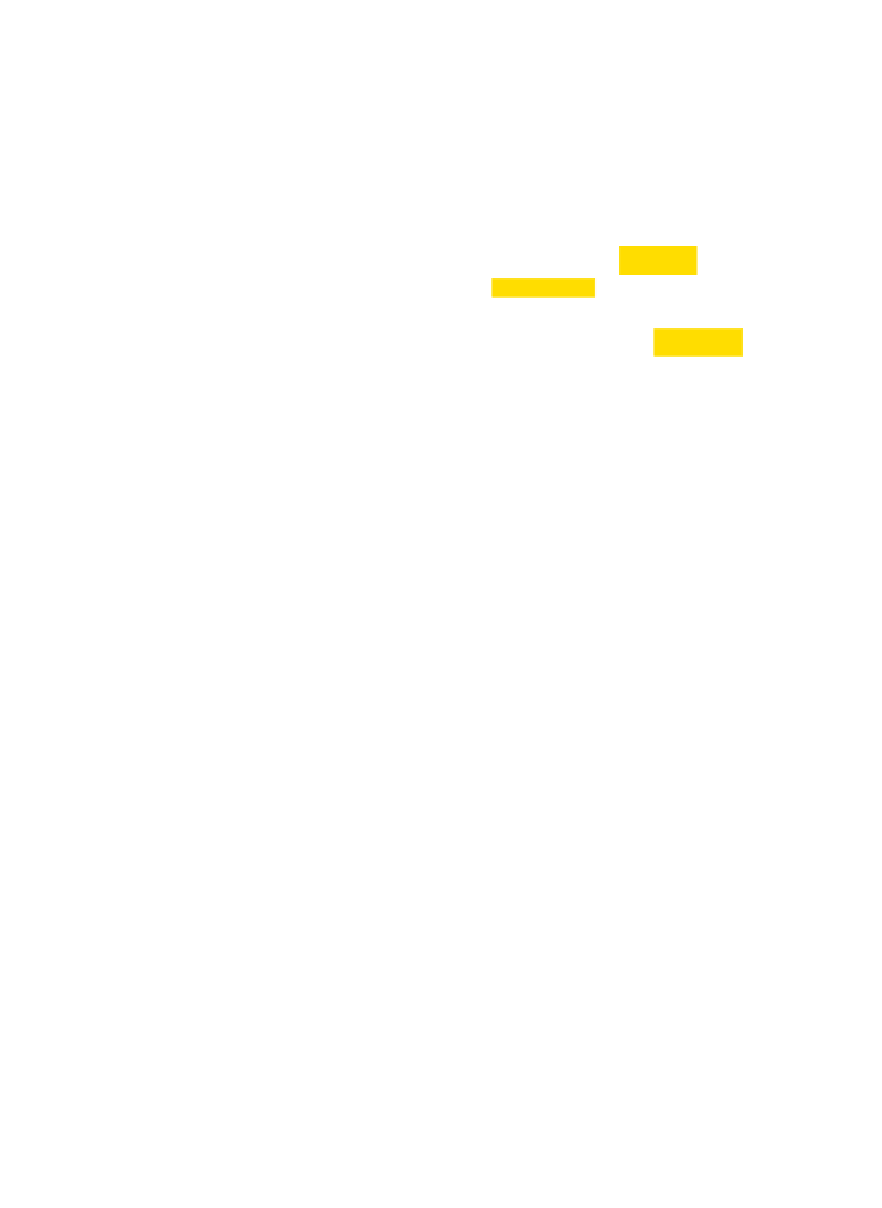

Figure 7.1.2

Filtration using membranes

Figure adapted from Koch Membrane Company.

Figure 7.1.2

illustrates the types of separations that are carried out by

fi ltration. We see that through microfi ltration we can remove bacteria

from water. However, if we would like to use this sieving mechanism for

gas separation, we will need to make materials with very narrow pores.

In fact, if we were to plot the molecular weights of the gasses we are

interested in separating on

Figure 7.1.2

, we would see they are outside

the scale of “common” materials as defi ned in this graphic.

Membranes are often made of materials that are common and not

too expensive, such as rubber, polycarbonate, or polyimide. While not

exactly cheap either, they are common and accessible and can be made

in large quantities. A signifi cant number of applied technologies presently

use membrane processes for large volumes of fl uids. It is not too much

of a stretch of the imagination to think that membrane separation could

become part of CCS.

Search WWH ::

Custom Search