Environmental Engineering Reference

In-Depth Information

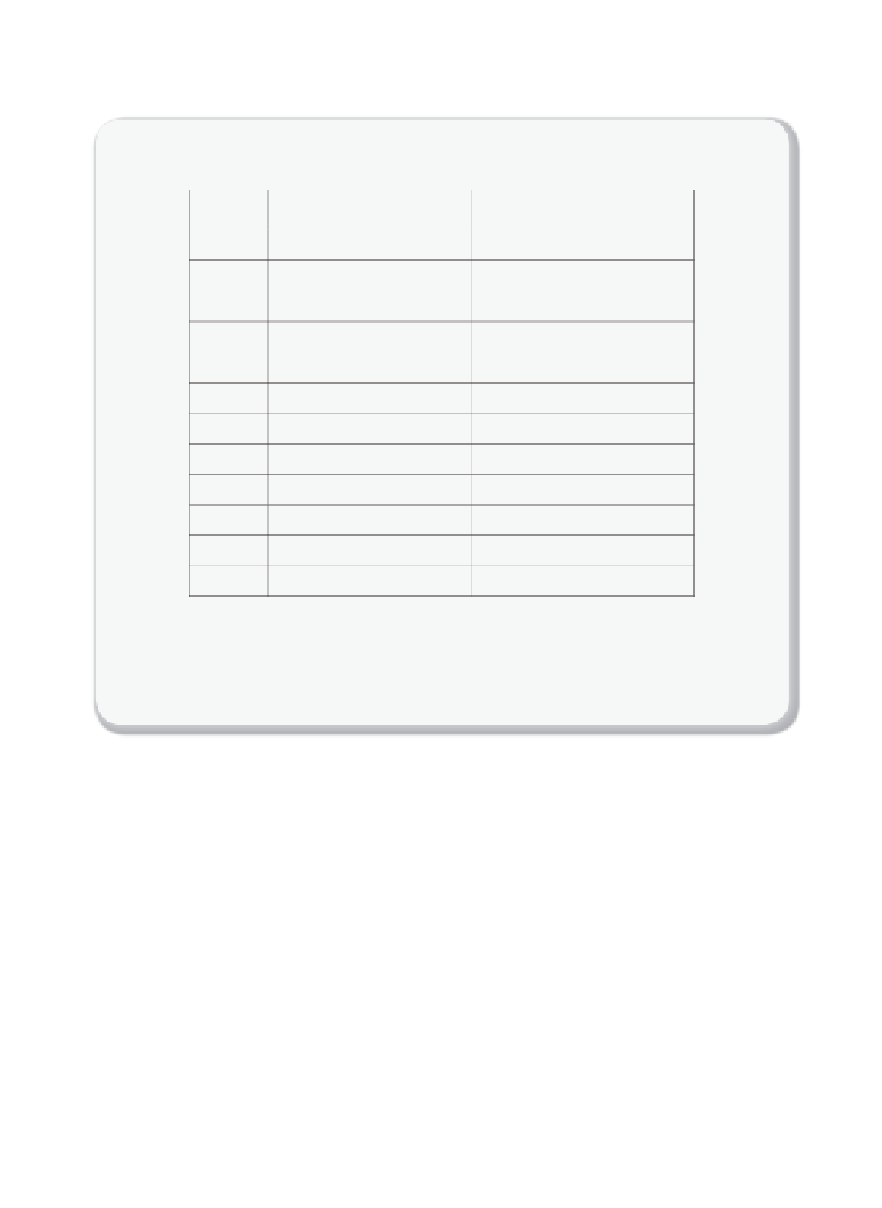

Table 6.6.1

Total use of metals for worldwide carbon capture

using MOFs

Metal

Use for CCS in %

Total use (until 2050) in %

Fe 0.080 0.02

Al 2.2 0.2

Cu 5.6 2.3

Mn 7.0 2.3

Zn 7.5 5.9

Cr 12 12

Mg 14 1.9

Ti 23 3.6

Ni 58 19

Zr 103 36

Co 1,030 200

V 1,620 110

Suppose we implement CCS using MOFs, how will this affect the mining of

metals? The first column gives the use of metals for MOFs in CCS as a

percentage of the 2010 global reserves. The second column gives the total

use of the metals until 2050 as a percentage of the estimated global

reserves of each metal.

Data from Sathre and Masanet

[6.39].

Table 6.6.3

, the different cost components are compared. This table

illustrates that the bulk of the costs are from the capture process; the

transport and storage only account for 10-15% of the total costs. These

numbers translate into an increase in the price of electricity of about 51%

by 2050. Also note that in the initial stages of the implementation the cost

of CCS will be much more expensive; the fi rst CCS operations will be the

most expensive, but by the implementation of the second generation the

costs will go down rapidly.

This table also shows that a process based on Mg-MOF-74 will cost

$76 per tonne of avoided CO

2

emission, compared to $68 for the MEA-

based process. This is a surprising result — we would have expected the

amine process to be much cheaper as MOFs are expected to be more

expensive to synthesize. The details in the study of Sathre and Masanet

show that the costs of absorption/adsorption materials, MEA or MOF, are

Search WWH ::

Custom Search