Environmental Engineering Reference

In-Depth Information

500

MEA

PZ

400

300

200

100

0

2000

2002

2004

2006

2008

2010

year

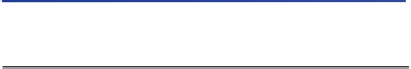

Figure 5.7.2

The parasitic energy of an amine capture process

This fi gure shows how different process designs and different solvents (MEA and PZ)

have reduced the parasitic energy over the years. The blue line represents the thermo-

dynamic minimum.

Data from Rochelle et al.

[5.13].

process we can also analyze and estimate the minimum energy required

for each step in the overall process. Professor Gary T. Rochelle and

co-workers at the University of Texas at Austin analyzed the amine cap-

ture process shown schematically in

Figure 5.7.3.

In this fi gure, we

recognize the absorber and the heat exchanger. For the stripper a two

stage process is used, where a fi rst separation is achieved at a higher

pressure than the second one. In the condenser, water is removed from

the CO

2

gas stream before the compression stage. In this process, a

fl ue gas with 12% CO

2

at 40ºC is considered and it is assumed that

90% of the CO

2

is captured and compressed to 150 bar.

Rochelle and co-workers estimated the minimum required energy by

calculating the minimum lost work in each step of the process. The idea

of a lost-work analysis is that any irreversibility in the process creates

additional entropy that is lost for the process. As we recall from fi rst year

thermodynamics, a truly reversible process requires infi nitely small steps

and infi nitely small perturbations from the equilibrium confi guration. In

practice, “infi nitely small” can be approached by building very large

equipment such that the fl ow is so slow that the system is practically at

equilibrium. However, the costs of such equipment will be prohibitively

Search WWH ::

Custom Search