Environmental Engineering Reference

In-Depth Information

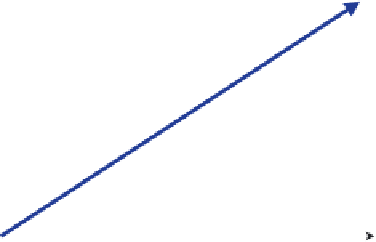

“step down” between the slopes of these two lines by forming a series of

triangles. Each of these triangles, or stages, represents mass conserva-

tion and thermodynamic equilibrium at one plate in our absorber.

Let us now look at a typical absorber, which is using pure water as

the solvent at 25ºC. Flue gas vapor from a coal-fi red power plant is com-

ing in with a CO

2

concentration

y

fl ue

CO

2

=

0.12. Water is exiting the absorber

with some concentration of CO

2

(

x

reg

CO

2

). Let us assume a certain

n

sol

/

n

fl ue

ratio. We start at plate number one in the bottom of our absorber (see

Figure 5.2.7

). As we are at the bottom of the column, the gas entering

the plate is the fl ue gas,

y

CO

2

(1)

CO

2

, the mass balance equation gives

us the corresponding liquid concentration, x

CO

2

(2). If we assume equilib-

rium on each plate, the gas that is leaving this plate has a CO

2

concentra-

tion of

y

CO

2

(2), according to Henry's law. We now have our fi rst stage in

the absorber. Now we can apply the mass balance and Henry's law to

obtain

x

CO

2

(3) and the corresponding

y

CO

2

(3) — and in this way we are

adding stages, each of which represent a plate. Ultimately, the stages will

terminate with concentrations

x

reg

y

fl ue

=

CO

2

at the top of the absorber. This

form of analysis is called a

McCabe-Thiele method,

named for the two

MIT chemical engineers who developed it in the 1920s.

Figure 5.2.7

gives us an intuitive sense of how plate absorption columns operate.

CO

2

,

y

exh

y

CO

2

flue

y

CO

2

#1

#2

exh

y

CO

2

#3

x

CO

2

reg

x

CO

2

Figure 5.2.7

Absorber with three stages

Search WWH ::

Custom Search