Environmental Engineering Reference

In-Depth Information

There are several types of pre-combustion capture:

oxycombustion

,

integrated gasifi cation combined cycle

(

IGCC

), and

chemical looping

[4.1]. These differ in their methods of integrating the technology into a

power plant, as illustrated in

Boxes 4.1.2, 4.1.3,

and

4.1.4,

respectively.

From a gas separation point of view, the IGCC process involves the con-

version of coal into

syngas

, a mixture of CO and H

2

. The separation of

these two gasses is an important step in the IGCC process. In contrast,

chemical looping avoids the need for separation of oxygen from air.

An obvious question at this point is: which technology is the best? As

we will see, this is a very diffi cult question to answer. Take the issue of

cost, for example. The main difference between pre-combustion and post-

combustion technologies is in construction. While post-combustion instal-

lations can be added onto existing power plants, as we saw, implementing

pre-combustion carbon capture technology in an existing power plant

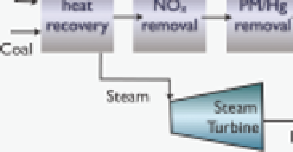

Box 4.1.2

Oxycombustion (Pre-combustion carbon capture)

In the oxycombustion process coal is burned using pure oxygen. The pure oxygen is

obtained from a cryogenic air separation unit (ASU). Burning coal with pure oxygen

would produce temperatures that are too high for the currently available boiler materi-

als. The temperature is reduced by recycling part (70-80%) of the fl ue gasses and

mixing this with pure oxygen. The resulting fl ue gas contains water and carbon diox-

ide, which can easily be separated. Pulverized coal (PC) is burned in a boiler, which in

this particular case does not use selective catalytic reactors (SCR) for controlling NO

x

emissions. Wet limestone is used for fl ue gas desulphurisation (FGD).

Search WWH ::

Custom Search