Environmental Engineering Reference

In-Depth Information

7.2.6 G

ENERATOR

E

XAMPLES

At rated power, generators are very efficient; however, at low power levels the efficiency decreases.

Therefore, some wind turbines have two generators, one for lower wind speeds. The Vestas V47

had a 200 kW and a 660 kW generator. Another way is to switch between number of poles,

six poles for low wind speed and four poles for higher wind speeds. The Bonus generator was

260/1300 kW.

The generator for the MOD-5B was rated at 3.2 MW, and was a variable-speed (1,330-1,780)

wound-rotor induction generator. A cycloconverter system maintained a constant-frequency output.

The Westinghouse, 600 kW, wind turbine had a synchronous generator, and frequency was con-

trolled by the variable pitch of the blades. A power control algorithm limited high instantaneous

power output (spikes caused by wind gusts) by derating the maximum power by 10% when a power

spike exceeded 800 kW.

Large wind turbines can be operated at variable-rpm, maximum

C

P

operation. This means

low-rpm generators with a large number of poles. Project Eole located at Cap Chat, Canada,

was a large VAWT rated at 4 MW. Since this was a direct-drive system, the generator was quite

large, 12 m in diameter with 162 poles. The output was rectified to DC and then inverted back

to 60 Hz AC. The unit only operated for around 10,000 hours, and power output was limited

to 2.5 MW.

Enercon, a German manufacturer, developed large-ring generators to eliminate the gearbox

on large wind turbines. The output is rectified and then converted to constant frequency. Over

10,000 units have been installed from 300 kW to megawatt units. In 2007, it built a 6 MW unit,

126 m in diameter (E126).

The Sandia VAWT test bed (34 m diameter, rated at 500 kW), which was located at USDA-ARS,

Bushland, Texas, was designed as a variable-speed, constant-frequency system. The system was a

load-commutated inverter, AC-adjustable speed drive, with a synchronous motor/generator rated

at 625 kW. Such systems are currently operated in industrial applications. Power electronics and

inverters allow wind turbines to operate at either constant or variable rpm.

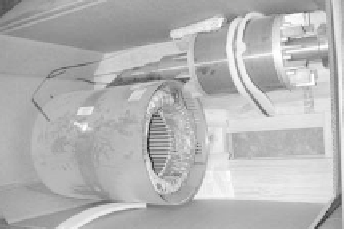

Jay Carter Sr. developed a wind turbine with the same rotor, hub, and drive train, which has two

induction generator options: six poles, 30 kW (wind rotor 60 rpm) for medium wind speed regimes,

and four poles, 50 kW (wind rotor 90 rpm) for good wind speed regimes (Figure 7.11).

Higher-voltage generators are used in some wind turbines. A Spanish manufacturer developed a

geared wind turbine with a brushless synchronous generator and a full converter.

The size of the wires connecting the generator to the grid depends on the current and distance

to the connection. For small wind turbines, manufacturers will recommend wire sizes for different

FIGURE 7.11

Left: Generator, gear box, and Jay Carter Sr. Right: Stator and rotor of generator, 50 kW.

Search WWH ::

Custom Search