Environmental Engineering Reference

In-Depth Information

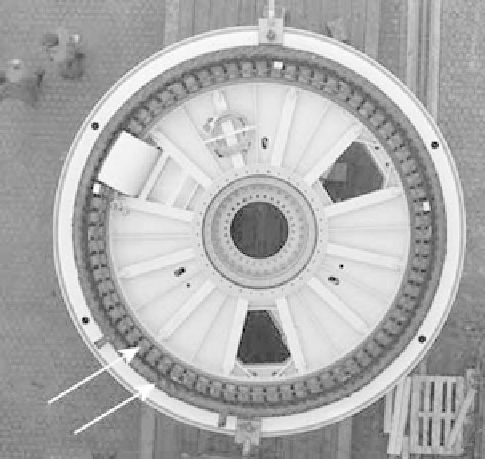

Rotor

Stator

FIGURE 7.10

Ring generator for gearless Enercon, E66. Size can be estimated from the two men in the upper

left corner. (Photo by Thomas Schips. With permission.)

7. 2 . 3 D

IRECT

-D

RIVE

G

ENERATOR

, V

ARIABLE

-RPM O

PERATION

There is no gearbox and the generator operates at the same rpm as the wind rotor, 10 to 25 rpm, for

megawatt wind turbines. These generators are very large (Figure 7.10), and the output is converted

to constant frequency and voltage by power electronics. Again, control is by pitch of the blades. So

here the trade-off is between no gearbox and a large generator with power electronics.

7.2.4 P

ERMANENT

M

AGNET

A

LTERNATOR

, V

ARIABLE

-RPM O

PERATION

This is also a direct-drive system with no gearbox, and it is common on small wind turbines. The

most common control for high winds is by furling using a tail. However, Southwest Wind Power has

a downwind unit where electrodynamic braking is used for high winds and shutdown. Some larger

permanent magnet alternators are available (500 kW), and General Electric has a 2.5 MW unit.

The advantages of permanent magnet excitation are lower losses, lower weight, and lower cost. A

disadvantage is that the excitation cannot be controlled.

7. 2 . 5 G

ENERATOR

C

OMPARISONS

All the above generators have been used in wind turbines. So there is a trade-off among (1) cost,

size, and weight, (2) suitability for grid frequency, (3) blade noise, (4) energy production, (5) reliabil-

ity and maintenance, (6) power quality, and (7) grid faults [9]. Many manufacturers have changed

from constant- to variable-rpm operation because of energy production and smoother power due

to inertia of the wind rotor. In the final analysis, the choice for the electric conversion depends on

energy produced (annual) and the cost per kilowatt-hour from the wind turbine.

Search WWH ::

Custom Search