Environmental Engineering Reference

In-Depth Information

components are nacelle, 70 metric tons; rotor, 41 metric tons; and tower, 160 metric tons. The tower,

which is 80 m tall, was composed of four sections on a foundation that required 460 m

3

of concrete,

which included a small pad for the transformer.

6.10 SMALL WIND TURBINES

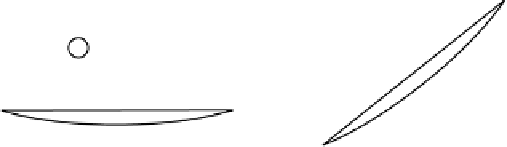

Generally small horizontal-axis wind turbines are kept facing into the wind by a tail. The control

mechanism to reduce power in high winds is that the rotor axis is offset from the pivot point, axis of

connection to the tower (Figure 6.24). Therefore, there is more force on one side of the rotor than the

other, which tries to move the rotor parallel to the wind; however, the wind force on the tail keeps

the rotor perpendicular to the wind. For high winds the unequal force on the rotor is greater than the

force of the tail; therefore, the rotor moves parallel to the wind. For very small rotors the tail may

be fixed, and during medium to high winds with rapid change in direction, sometimes these wind

turbines will turn completely around the yaw axis, a 360° revolution. Most of the wind turbines have

a hinge for the tail, and for high winds, the rotor moves to a position closer to parallel to the tail,

called furling [47-49]. Then when the winds decrease, the tail returns to a position perpendicular

to the rotor by a force due to springs or gravity. Dampers, like shock absorbers, can keep this move-

ment from happening too rapidly, both for furling and for restoration to normal operation. The farm

windmill uses springs, the length of which is adjustable for the restoring force. One mechanism to

use gravity is to have the tail hinge at a slight inclined angle to the vertical plane.

Performance was measured for a 2 kW wind turbine for water pumping for changes in the param-

eters of the offset of the rotor axis to the yaw axis, length of tail boom, area of tail, and pitch angle

[50]. Four different tails and two different yaw axis offsets were tested because the furling behav-

ior was critical to the performance [51]. Overall, nine different configurations were tested, which

included two sets of blades with different pitch angles to try to improve the performance at low

wind speeds.

The pivot point does not have to be around the vertical axis (yaw); it can also be about a hori-

zontal axis, which would produce vertical furling. The rotor and generator on the North Wind

high-reliability turbine had a horizontal pivot for the rotor and generator, a coil spring damper,

and the restoring mechanism was gravity. Another horizontal pivot was unique in that the rotor

Yaw axis

Yaw axis

Wind

Wind

FIGURE 6.24

Diagram of rotor axis offset from yaw axis with hinged tail for furling.

Search WWH ::

Custom Search