Environmental Engineering Reference

In-Depth Information

16

14

12

10

8

6

4

2

0

0

1

23456 789

10

Speed Ratio

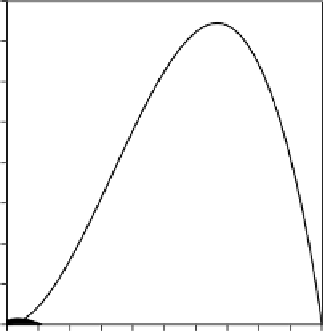

FIGURE 6.4

Comparison of power/area for a translating drag device (small solid curve) and a translating lift

device versus speed ratio of the device to the wind.

and the value of the axial interference factor is substituted into the equation to obtain the power/

area for a lift device:

P

A

3

RAA

2

0.5

v

4

(

1

)

(6.20)

0

A lift device can produce much more power per area of blade than a drag device (Figure 6.4).

Notice the small black line is for the drag device, which reaches a maximum of around 0.22 at a

speed ratio 0.3. The maximum for the lift device is around 15 at the speed ratio 2/3 of the ratio of

lift to drag coefficients. For this example, the power per area of blade was calculated for the drag

device with a drag coefficient of 1.5, and for the lift device, the ratio of lift coefficient to drag coef-

ficient was 10. Thus, the lift device can easily produce fifty times the power per blade area—another

reason drag devices are not used to produce electricity, although a company in South Africa has a

farm windmill that has an option for an electric generator.

6.5.1 M

AXIMUM

T

HEORETICAL

P

OWER

The maximum power/area can be found by plotting the curve

P/A

versus

]

(Equation 6.20) or by

using calculus. The answer is

]

1/3 or 1. Of course,

]

1 means that there is no reduction of wind

speed and the disk does not take out any power. For

]

1/3, the maximum power is

P

A

16

27

3

0.5

R

v

(6.21)

0

Therefore, the maximum power coefficient, from Equation 6.6, is

C

P

16/27 0.59. Real rotors

will have smaller power coefficients due to drag, tip and hub losses, losses due to rotation of the

wake, and frictional losses; however, measured values can reach 50% (which includes drive train

and generator). This is another reason lift devices are used to generate electricity, compared to drag

devices, as the maximum theoretical power coefficients are 50% versus 20%. However, the farm

windmill, which has some of the same characteristics as a drag device (large solidity, low tip speed

ratio) is well designed for the application of pumping low volumes of water.

Search WWH ::

Custom Search