Environmental Engineering Reference

In-Depth Information

temperature. This may be attributed to the enhanced conversion of asphaltenes to light

products. Consequently, the HDM rate should be increased as well.

At the same temperature, the H

2

pressure may be a critical parameter for controlling coke

formation. It is however believed that the decreased coke formation caused by an increase in

the H

2

pressure would favor the deposition of metals relative to that of coke. Richardson et al.

[212]

used Athabasca bitumen to study the H

2

pressure effect on the initial coke formation

(between 1.5 and 5 h on stream) in the continuous stir tank reactor (CSTR) system and in an

autoclave reactor using the commercial NiMo/Al

2

O

3

catalyst at 703 K. After a rapid coke

build-up during the first hour on stream, the coke formation did not change with the increasing

ratio of the feed to catalyst. At the same time, increasing H

2

pressure from 7MPa to more than

15MPa decreased the amount of coke from about 17 wt.% to about 11 wt.%. In the study of

Gualda and Kasztelan

[145]

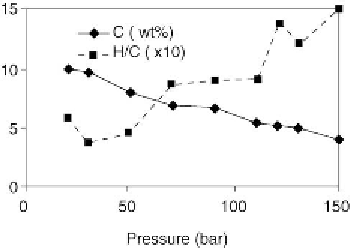

on hydroprocessing an atmospheric residue, the amount of coke

decreased from about 10 wt.% to about 4 wt.% by increasing the H

2

pressure from 2 to 15MPa

(

Fig. 4.17

). Moreover, the H

2

pressure had a pronounced effect on the H/C ration of coke on

the catalyst.

Figure 4.18 [212]

shows the effect of H

2

pressure on the steady-state level of

coke. It is believed that in the case of Athabasca bitumen, large asphaltenic molecules had the

predominant role during the initial stages of coke formation. Thus, there was a sufficient

amount of asphaltenes to form the same amount of coke even for the low feed/catalyst ratios.

Higashi et al.

[213]

studied the coke deposition on catalyst surface during the very early stages

on stream at a low H

2

pressure using an atmospheric residue as the feed. The study was

conducted in a pilot plant. They observed that the coke could not be removed and/or catalyst

activity could not be recovered by increasing the H

2

pressure at the same temperature, during

the later stage on stream. This indicated the permanent deactivation by coke. It is therefore

essential that the coke deposition control by H

2

pressure begins at the start of the run. In this

case, the loss of the HDS activity was noticed in particular. It was observed that the catalyst

presulfiding was an important factor in controlling the initial coke deposition.

Figure 4.17: Effect of H

2

pressure on H/C ratio and amount of carbon on catalyst (NiMo/Al

2

O

3

,

atmospheric residue [AR], 663 K) [From ref.

145

. Reprinted with permission].