Environmental Engineering Reference

In-Depth Information

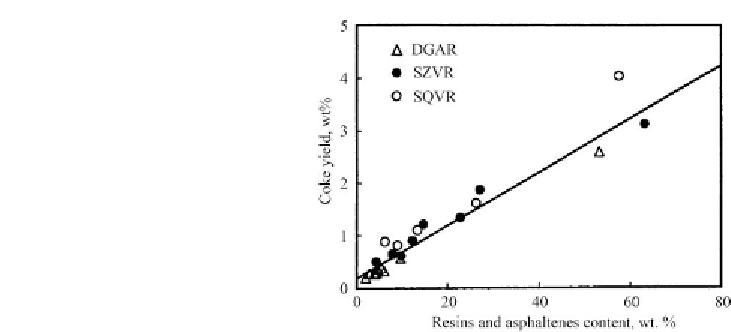

Figure 4.10: Coke on catalyst as function of the content of resins and asphaltenes in fractions

from Dagang AR (DGAR), Saudi light VR (SQVR) and Saudi medium VR (SZVR) at 673 K and

8.5MPa of H

2

over NiMo/Al

2

O

3

[From ref.

191

. Reprinted with permission].

unlikely that these observations can be generally applied to all heavy feeds because the

chemical structure of asphaltenes may be another parameter influencing coke deposition.

Thus, for heavy feeds having a similar content of asphaltenes, but of different chemical

structure, the coking propensity increased with the increasing aromaticity of asphaltenes.

It is believed that during very early stages of the operation, there is little effect of metals on

coke formation. On the other hand, the coke formed initially can have a pronounced effect on

the rate of the metal deposit formation because of the partial pore plugging by coke. Moreover,

this part of the support on which metals could deposit was already occupied by coke. It is

therefore critical that the rate of coke formation is kept at minimum to ensure a high HDM

activity of catalysts. In this regard, the results in

Fig. 4.4 [174,175]

can have important

implications on the design and preparation of the HDM catalysts, although they were obtained

for a VGO feed. Thus, the coke formation may be kept at a minimum by selecting an optimal

composition of catalyst. At the optimal composition, formation of the “chemical coke”

associated with hydroprocessing reactions is slow, thus ensuring a high HDM activity due to

the diminished interference by coke. However, this was not confirmed in the study involving

the Kuwait atmospheric residue (90 ppm of V+Ni; 3.6 wt.% asphaltenes) conducted by Marafi

et al.

[193]

who compared the Mo/Al

2

O

3

(3 wt.% Mo) with NiMo/Al

2

O

3

(8 wt.% Mo and

2 wt.% Ni) catalysts having pore volume of 0.7 and 0.5mL/g, respectively. Typically, the

catalysts were used for HDM and HDS, respectively. Between 633 and 693 K and at 12MPa,

consistently more coke was deposited on the HDM catalyst. As expected, the H/C ratio of coke

on the HDM catalyst was much lower than that on the HDS catalyst because of the higher

HYD activity of the latter. The contradictory results reported in the literature underline

complexity of the simultaneous deactivation of catalyst by coke and metals, particularly during

the initial stages. This may be attributed to the differences in experimental conditions. This is