Environmental Engineering Reference

In-Depth Information

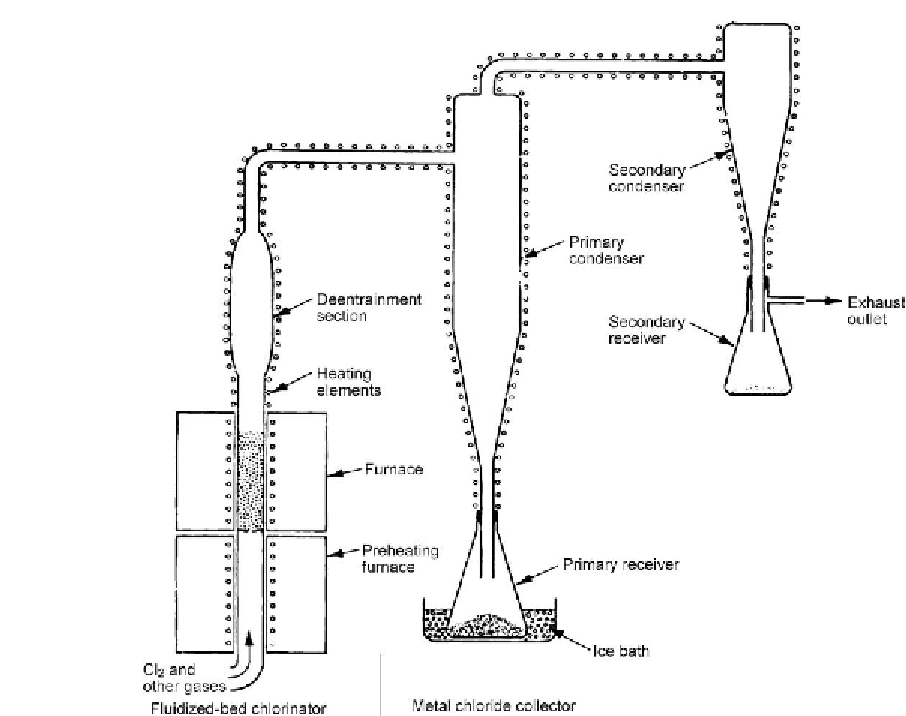

Figure 11.19: Apparatus for chlorination of waste catalysts [From ref.

636

. Reprinted with

permission].

from the purified solution at about pH 5 with Na

2

S. The chlorination step extracted 73 to

99 wt.% of the Ni, 61 to 99 wt.% of the Co, 73 to 95 wt.% of Mo, and 82 to 98 wt.% of the W.

In the final recovery step, solvent extraction recovered over 99 wt.% of the Ni from the purified

solution. Over 98 wt.% of the Ni or Co was recovered by sulfide precipitation. The maximum

overall recoveries for Ni, Co, Mo, and W in weight percent were 98, 97, 80, and 88,

respectively.

Further investigations on the recovery of metals (V, Mo, Co, and Ni) from spent

hydroprocessing catalysts without Al by selective chlorination were carried out by Gaballah

et al.

[666,667]

in the mid-nineties. Both roasted (decoked) and unroasted (coke containing)

spent catalysts were used in the chlorination study and the efficiency of metal recovery from