Environmental Engineering Reference

In-Depth Information

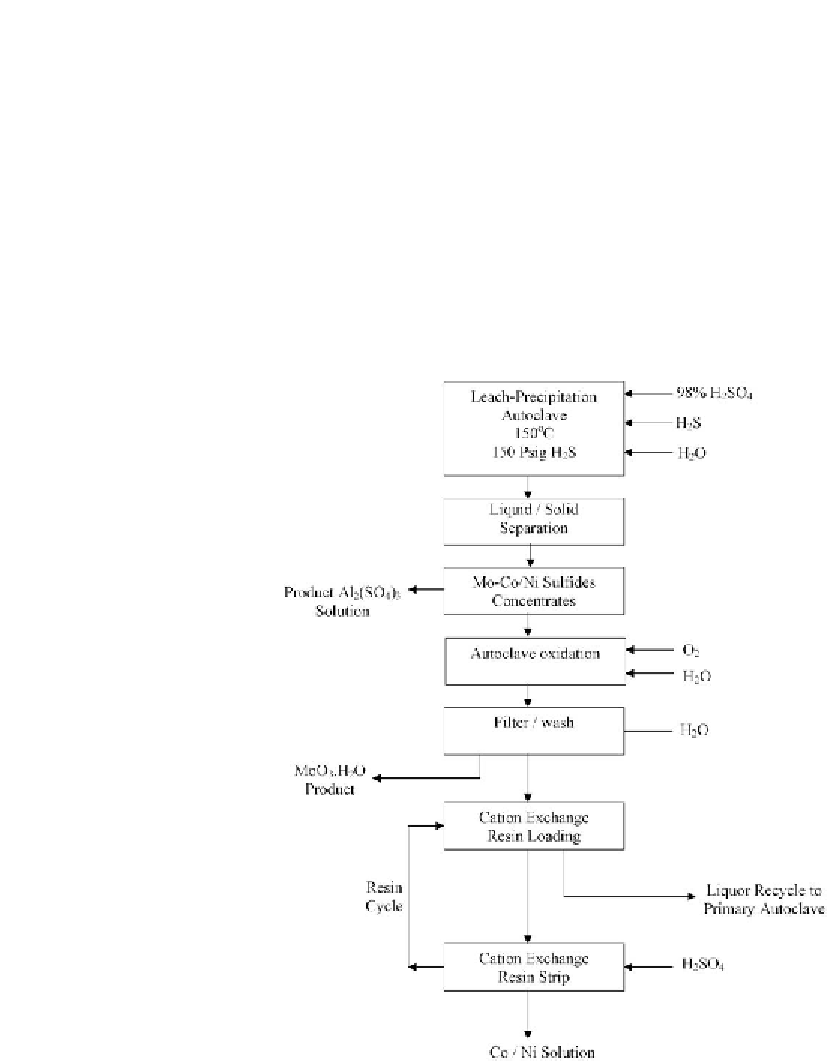

In the patented process developed by Hyatt

[620]

, the spent CoMo/Al

2

O

3

catalyst was treated

with sulfuric acid in the presence of H

2

S under pressure (7.5-15 atm) in an autoclave at

100-200

◦

C. The presence of H

2

S resulted in the precipitation of Mo and Co as sulfides while

the Al

2

O

3

was converted to soluble Al

2

(SO

4

)

3

. The metal sulfides were separated from the

Al

2

(SO

4

)

3

solution and subjected to oxidation under pressure in an autoclave to convert MoS

2

to solid molybdic acid and the CoS to CoSO

4

. The molybdic acid was separated by filtration

from the CoSO

4

solution. The cobalt was recovered by ion exchange. A schematic flow

diagram of the process is shown in

Fig. 11.5 [620]

. The extraction and recovery of valuable

metals, such as Mo and Co together with the alumina as Al

2

(SO

4

)

3

, could be achieved in this

process. Recovery of V is not reported in this acid leaching study.

Figure 11.5: Primary steps for the separation of metals from spent hydrodesulfurization (HDS)

catalyst by H

2

SO

4

in the presence of H

2

S [From ref.

620

. Reprinted with permission].