Environmental Engineering Reference

In-Depth Information

1.92 wt.% MoO

3

, 3.2 wt.% NiO, and 39.6 wt.% Al

2

O

3

, by leaching with the aqueous NH

3

(15-17M) solution at room temperature. Mo and Ni were not leached from the spent catalyst

under these conditions used in the study

[617]

. In a recent study, Yoo et al.

[618]

used

ammonium sulfate solution for leaching Ni from the spent hydrodesulfurization (HDS)

catalyst. About 94% of Ni was leached from the catalyst with 2.6mol/L (NH

4

)

2

SO

4

solution at

the temperature 368 K. The extent of leaching of other metals from the spent catalysts was not

reported in this study.

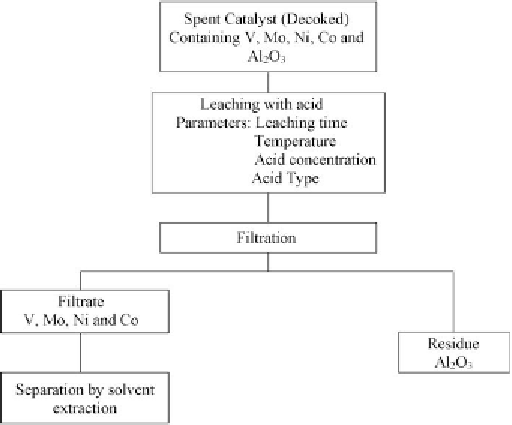

11.1.1.2 Leaching with Acids

Extraction of the metals present in spent hydroprocessing catalysts by leaching with acids has

been studied extensively by many researchers. It became evident that various types and

concentrations of inorganic acids, such as HCl, H

2

SO

4

, and HNO

3

, have been used as leaching

solutions. Among organic agents, water-soluble organic acids have been attracting most of the

attention. Compared with inorganic acids, aqueous solutions of organic acids ensure an

environment requiring much less safety precautions. A generalized scheme for leaching with

acid is shown in

Fig. 11.2

.

11.1.1.2.1 Inorganic acids

In the study of Valverde et al.

[619]

, more than 95% of Co, Ni, and Mo were leached out using

9MH

2

SO

4

at 90

◦

C within 70-90min at stirring rate of 200 rpm. The acid/catalyst ratio,

estimated from the stoichiometric amount of acid required for the conversion of all metals to

Figure 11.2: Metal extraction using acid.