Environmental Engineering Reference

In-Depth Information

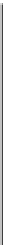

Table 9.6: Free energies for reactions of metal oxides with H

2

S [From ref.

424

. Reprinted with

permission].

Reaction

G

At 800 K

At 900 K

MoO

3

+2H

2

S =MoS

2

+2H

2

O

−

21

.

4

−

16

.

7

CoO+H

2

S = 1/9Co

9

S

8

+ 1/8S

2

+H

2

O

−

14

.

3

−

14

.

2

NiO+H

2

S = 1/3Ni

3

S

2

+1/6+S

2

+H

2

O

−

11

.

4

−

12

.

0

ZnO+H

2

S=ZnS+H

2

O

−

17

.

7

−

17

.

7

Fe

3

O

4

+4H

2

S=FeS+FeS

2

+FeO+4H

2

O

−

21

.

6

−

22

.

9

FeO+H

2

S=FeS+H

2

O

−

10

.

2

−

10

.

3

Traditionally, the gas clean-up has been performed using a combination of Claus and Scott

processes which are usually integral part of commercial operations such as petroleum

refineries and gasification plants employing coal and petroleum coke as feedstocks.

Commercial gas clean-up sorbents contain oxides of Fe, Zn, Ni, Cu, and Ca

[550]

. The H

2

S

contaminant is removed from the gases by reacting with metal oxides according to the

following general equation in which Me represents metal:

MeO

+

H

2

S

=

MeS

+

H

2

O

Therefore, before being used as gas clean-up sorbents, spent hydroprocessing catalysts have to

be decoked. The particle size and shape suggest that after decoking spent catalysts can be used

directly in the fixed-bed gas cleaning reactors. After saturation with sulfur, the fixed-bed is

oxidatively regenerated to be used in next cleaning cycle. The sulfur oxides containing off-gas

is contacted with a solution of lime to produce high purity gypsum which is marketable

product.

Table 9.6 [424]

lists the tentative reactions involving metal oxides in decoked catalysts with

H

2

S. The large driving forces for the H

2

S removal, as indicated by negative

G values,

confirm the suitability of spent catalysts for gas clean-up. This was experimentally confirmed

using three spent-decoked catalysts shown in

Table 9.7 [551]

. Breakthrough time's

correlations which are used to determine cleaning efficiency of the sorbents are shown in

Fig. 9.11 [551]

. Such correlations are established in a fixed-bed reactor using a simulated coal

gasification mixture containing H

2

S. The breakthrough times determined in this way are listed

in

Table 9.8 [551]

together with those determined for the best-known commercial sorbent such

as zinc ferrite. The first glance comparison indicates superiority of zinc ferrite; however, this

difference diminishes significantly when the comparison is normalized to the same amount of

active metals. Also, it has to be emphasized that the cost of zinc ferrite is about one order of

magnitude greater than that of the spent-decoked catalysts.