Environmental Engineering Reference

In-Depth Information

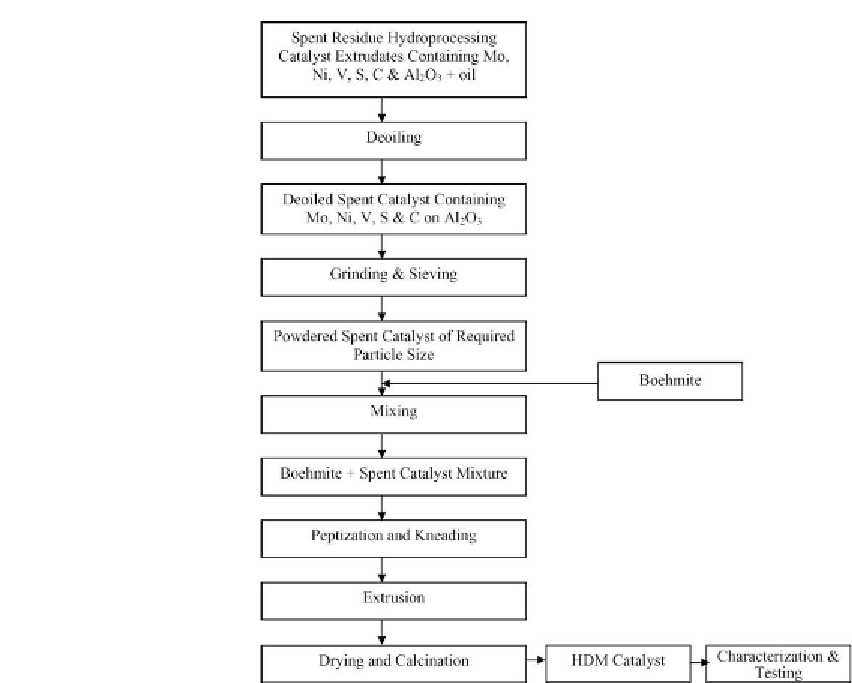

Figure 9.1: Operational steps in the preparation of catalyst extrudates from spent catalyst [From

ref.

9

. Reprinted with permission].

was maintained at 500

◦

C. Under these conditions, most of the coke was removed. After

de-oiling and/or decoking, catalysts were ground to obtain particle size in the range of 25 to

90

m, which was similar as that of boehmite. Boehmite used in the study was a commercial

product manufactured by Sasol, Germany. It was in a powder form and had particle size in

the following range:

<

25

m (8%).

This solid was used for mixing with the ground spent catalysts to obtain a paste suitable for the

extrusion. The sequence of operational steps used for the preparation of extrudates from

spent catalyst-boehmite mixtures are shown in

Fig. 9.1 [9]

.

m (3%), 25 to 45

m (9%), 45 to 90

m (80%) and

>

90

The concentrations of Ni, Mo, and V in spent catalysts A, B, and C (

Table 9.1

)

[522]

and

laboratory prepared catalysts were determined using the inductively coupled plasma atomic

emission spectroscopy (Varian Liberty II ICP-AES). A mercury porosimeter (Quantachrome