Environmental Engineering Reference

In-Depth Information

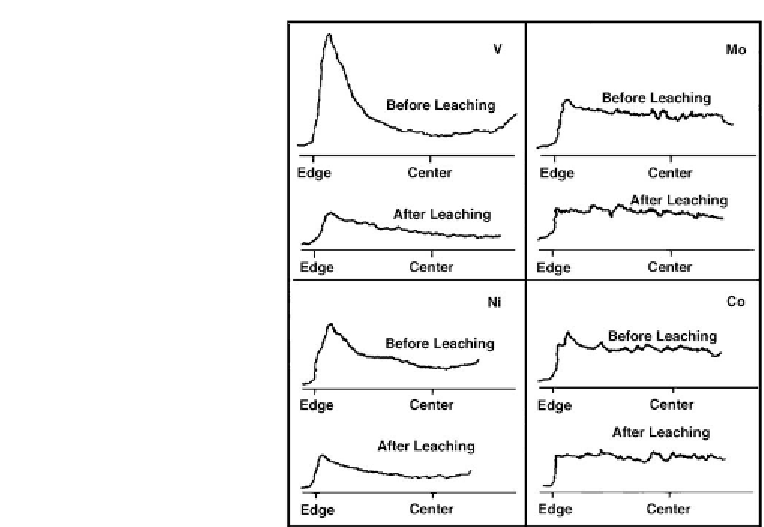

Figure 7.11: Effect of leaching on radial distribution of metals [From ref.

476

. Reprinted with

permission].

with the solution of oxalic acid

H

2

O

2

. Thus, after leaching, the distribution of the V and Ni

was significantly altered compared with little change in that of Co and Mo.

+

For coked catalyst, the metal oxidation began during the first contact of the catalyst surface

with the oxalic acid

H

2

O

2

mixture. At the same time, in the decoked catalyst, most of the

metals were already converted to an oxidic state during decoking. For coked catalysts, both

molecules of the acid and H

2

O

2

have to diffuse from the solution through the layer of coke to

reach the surface of particles. Among the metals present in spent catalysts, V will be oxidized

and leached out to the greatest extent compared with the other metals. Thus, the extensive

information in the literature confirmed that in spent catalysts, V is concentrated on the external

surfaces of particles as it is confirmed in

Fig. 7.11 [476]

. Under such conditions, a high

selectivity for leaching V is ensured. This is clearly confirmed in

Fig. 7.12 [484]

indicating

significantly enhanced selectivity for leaching V from coked catalyst compared with decoked

catalyst, i.e., for coked catalyst at about 80% V removal, the removal of Mo approached about

20% compared with more than 60% for decoked catalyst.

+

It is believed that there is an optimal ratio of the acid/H

2

O

2

giving the highest selectivity. The

optimum may be established experimentally. Moreover, the optimum depends on the origin of

organic acid and oxidizing agent. For example, a much greater enhancement in the selectivity