Environmental Engineering Reference

In-Depth Information

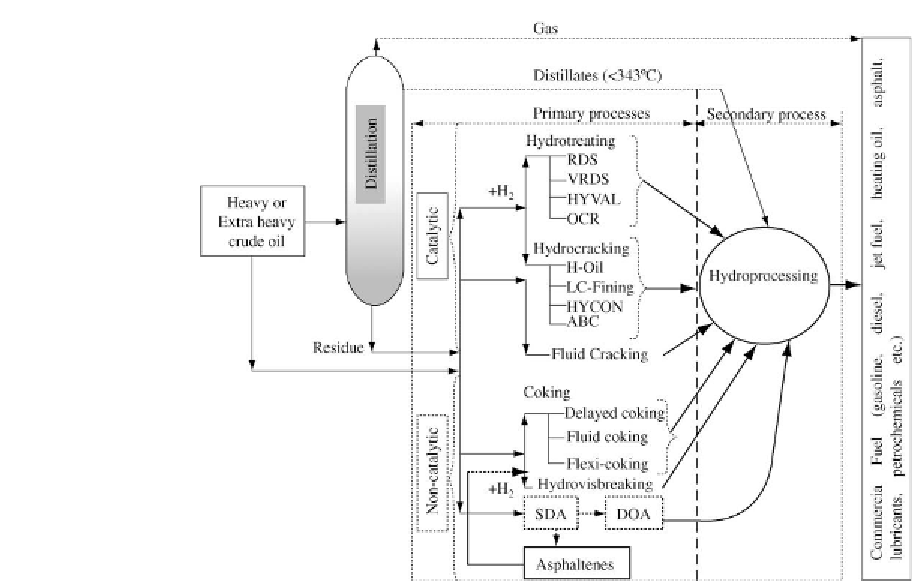

Figure 2.10: Advanced refinery for upgrading heavy and extra heavy feeds [From ref.

41

.

Reprinted with permission].

The transition from a conventional refinery (

Fig. 2.4

) to a more advance refinery resulted in the

increased consumption of electricity, steam and hydrogen per unit of processed crude and/or

commercial fuel produced. The flowsheet shown in

Fig. 2.11 [42,43]

indicates that the

advanced refinery must be capable of utilizing refinery residues to the extinction. This may

involve the production of additional liquids as well as that of electricity, steam and hydrogen

required for the operation of refinery. In the first step, the conversion of residues (e.g., coke) is

accomplished via gasification. The integration of gasification with petroleum refining

significantly improved the control of solid and gaseous emissions

[26,42,43]

. No other

technology besides gasification can offer such benefits. The generation of by-products such as

coke, asphalt and elemental sulfur as well as waste materials such as caustics, sludge and

contaminated water also increases compared with conventional refining. Today, the established

methods for utilization, handling and disposal of these by-products are available.

It has been recognized that the overall costs of handling the by-products and wastes per unit of

processed crude decrease with increasing size of refinery. The trends around the world indicate

on the integration of refineries with gasification technology allowing the conversion of coke